Safety Footwear Ratings: Everything You Need To Know

Style and colour may be your first thoughts when choosing new safety boots or shoes, but you should be more concerned about the Safety ratings of your chosen footwear. The fit, suitability for your job and the protection standards (aka: Safety Boot Ratings) should be at the forefront of your mind.

This is a guide to the safety standards, classifications, ratings and codes for work boots, protective shoes or in fact any workplace safety footwear. It will help you make the right choices to ensure you the correct level of protection for your feet. Whatever job you do or are buying footwear for, this guide covers it.

- Page Contents

- What You Need To Know

- Standard EN ISO 20345:2011

- Safety Rating Abbreviations & Codes

- Anti-Slip Footwear Ratings

- What Safety Footwear is Right For You?

- Comfort Levels

- Correct Level of Foot Protection

- Buying Second Hand

- Looking After Your Safety Footwear

Safety Footwear Regulations ARE PPE Regulations

All forms of PPE are covered and described by the Personal Protective Equipment (PPE) at Work Regulations 1992. An update was made in 2002, and another update happened in 2011.

It is an employer's responsibility to keep employees safe, including providing PPE and any other safety equipment workers may need. This absolutely includes safety footwear.

Safety Boot Ratings Are The Same for All Footwear

The safety footwear standards in the UK are the same as the footwear standards across Europe: EN ISO 20345:2011.

Safety Shoe ratings are the same as Safety boot ratings are the same as Safety Trainer ratings etc.

Under this standard, all safety footwear must protect the toes against a 200 joule impact. Be that work boots, wellingtons, safety shoes or safety trainers. It is understandable to think safety shoes may come under a different set of rules as foundry steelies - but you would be mistaken.

All safety footwear falls under the same regulations. A pair of safety trainers is comparable to a pair of safety Wellington Boots. A pair of nurse's non-slip clogs has the same legal regulations as the boots you would wear in construction. That regulation is called: EN ISO 2034:2011

So whatever footwear you need to use for your work tasks to keep your feet safe from injury or disease, you would follow the same guidelines and codes as for any safety boot.

Makes everything so much simpler when you only need to digest 1 set of guidelines.

What Does The Safety Footwear Standard EN ISO 20345:2011 Mean?

EN ISO 20345:2011 is not as complicated to understand as it first appears. It simply specifies the basic/additional safety footwear requirements to meet the standard.

Let's break it down...

- EN - This is the current applicable standard across Europe

- ISO - All footwear PPE products must meet the minimum safety standards as defined by the International Organization for Standardization.

- 20345 - This is the assigned legislation number.

- 2011 - This is the year the safety standard around footwear was updated. It now requires that safety footwear must now protect against a 200 Joule impact at the toes before failing.

ASIDE: There were some amendments to the standards in 2022 not included in this article yet. See the changes here.

Safety Footwear Abbreviations & Codes You Should Look Out For

There is an array of foot protection in the form of boots or shoes available apart from the standard toe-cap. For instance, some safety footwears are anti-static and some are ECD (Electro-Static Discharge) resistant. Some offer protection for the metatarsal, some have steel plates in the sole to prevent penetration and some prevent cuts (have you ever seen a chainsaw-proof boot?).

As is usual in PPE and Health & Safety, codes and abbreviations are used to describe these features. See the table below for a non-exhaustive list that is sure to grow with time.

| Code | Icon | Meaning |

| A | Anti-static | |

| AN | Ankle Protection | |

| C | Conductive | |

| CI | Cold Insulation | |

| CR | Cut Resistant Upper | |

| E | Energy Absorption | |

| FO | Fuel/Oil Resistant Outsole | |

| HI | Heat Insulation | |

| HRO | Outsole is Resistant to Hot Contact | |

| I | Electricity Insulated | |

| M | Metatarsal Protection | |

| P | Penetration Resistance | |

| WR | Water Resistance | |

| WRU | Water Penetration and Water Absorption Resistant Upper | |

| ESD | Electro-Static Discharge Resistant |

What are the Safety Footwear Ratings?

The above codes are very specific, but the level of protection footwear gives has a clear system of ratings combining many of the above codes. These are known as "S ratings". You are probably already familiar with some of them: S1, S2, S3 (and now S5).

This table lays out the 6 safety boot/shoe ratings - an explanation of each is below. Click on the rating to jump directly to it's full explanation.

| Rating | Icon | Meaning |

| SB | Safety Basic (Has Toe Protection) | |

| SBP | As SB with additional Mid-Sole protection against penetration | |

| S1 | Anti-Static, Oil-Resitant and Energy Absorption | |

| S1P | As S1 with additional Mid-Sole protection against penetration | |

| S2 | Prevents Water Penetration | |

| S3 | Midsole Penetration Resistance | |

| S4 | Leak-Proof | |

| S5 | Leak-Proof with Midsole Penetration Resistance |

What do the Safety Footwear ratings mean?

Please Note: After SB, the standards feature all the SB basics, but have extra protection or features.

- SB - Safety Basic - This is the basic standard for safety footwear and must have toe protection that can withstand a 200 Joule impact. There can be (and most likely will be) other standards alongside the SB which will appear as other symbols as mentioned above. EG: SB-FO would have the basic standard of safety toe-cap, but also features a Fuel/Oil Resistant Outsole.

- SBP - This is the same as the basic standard for safety footwear but includes a mid-sole plate (steel, or composite material) to protect the foot against penetration.

- S1 - S1 footwear is anti-static, resistant to fuel oil and features energy absorption at the heel. As with SB, other symbols can be added, EG: S1-HI would be an S1 shoe or boot, but is also insulated against heat.

- S1P - S1P footwear the same as S1 footwear but including a steel or composite plate in the Mid-Sole to protect against penetration from under foot.

- S2 - S2 footwear has all the aspects of S1 footwear, but adds prevention of water absorption for the upper. Again, codes can be added as they are with S1 and SB.

- S3 - You will find the same safety elements as contained in S2, plus a penetration resistant midsole. Again, codes can be added as they are with S2, S1 and SB. Find S3 rated safety footwear here.

- S4 - An S4 boot encompasses the same level of protection as an S1, however it is moulded from a polymer or rubber that makes them completely waterproof and leak-proof. A safety welly would be S4 at the least, and other codes can be added when the boot achieves other safety standards.

- S5 - S5 gives you all the safety footwear features of the S4, plus midsole penetration resistance. Here is an example of S5 safety boots.

The Non-Slip/Anti-slip Footwear Standards

Slips account for a huge percentage of workplace accidents, so it is absolutely vital that there are separate safety standards. Workers and employers need to be able to rate the slip-resistance of safety footwear.

Slipping is measured using 2 different lubrication mediums on 2 different surfaces, or both, using a "Pendulum Slip Test" system - a type of "Tribometer". That's a tool that measures the tribological quantities of the interacting surfaces in relative motion. Friction... it measures friction.

Here are the 3 standards

| Rating | Icon | Test Medium |

| SRA | Slip resistance is tested on ceramic tile which has been saturated with Sodium Lauryl Sulphate (the active ingredient in soap) | |

| SRB | Slip resistance is tested on Steel plate which has been saturated with Glycerol | |

| SRC | Slip resistance is tested and passed against the same conditions as SRA and SRB |

What Is the Best Safety Footwear for Me?

Knowing the safety standards and the conditions you will be working in is the first step to buying the correct safety boots, shoes or trainers for you.

You could stop reading here and still make an informed choice. However, there are other practicalities you should probably think about.

Here are some extra tips before you buy...

Comfortable Footwear is Key to Productivity

Have you ever trudged through mud in the garden, walking the hills or at a festival? The added weight on your feet makes every step more difficult and the consequence is pure misery.

That is not conducive to a good day at work!

More and more lightweight safety footwear is becoming available. No longer are the ugly old Miners external steel toe-caps the only solution to foot protection. Infact, those aren't even legal anymore and you should not be able to find them anywhere but a museum.

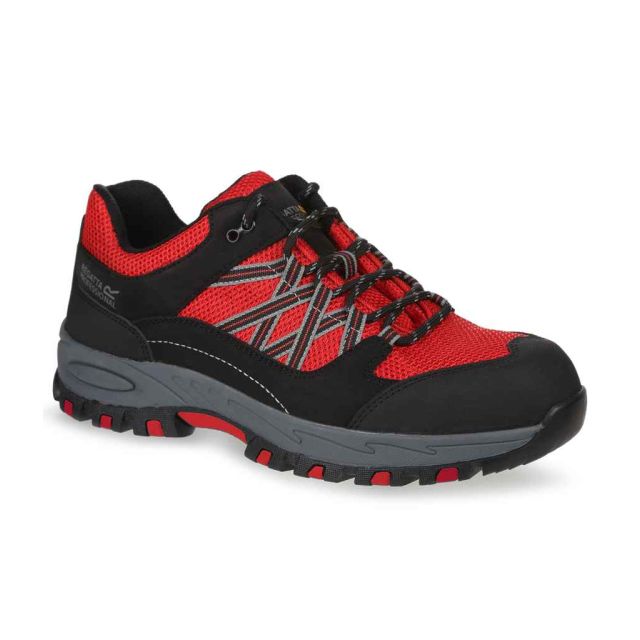

Modern technology has leapt forward allowing such trends as safety trainers, high protection wellington style boots, cut-resistance and all manner of other specialist foot protection - without compromising on comfort, flexibility and *ahem* style.

Ensure You Get The Correct Level of Foot Protection

Now you know what all the safety footwear ratings, standards and codes mean, you have no excuse for getting the wrong level of protection for your working environment.

Toe-protection is the minimum requirement for footwear to be classed as "safety", but there is a good chance you may require more.

Consider the work you do and the environment you do it in. Construction workers will definitely need the minimum of a toe-cap, but you would be wise to consider mid-sole protection too. You'd be glad of that if someone leaves a nail protruding from a 2 by 4. You should consider ankle support for uneven ground (that is why Rigger Boots are not really suited for building sites).

If you work with fuels or inflammables/flammables, you should use an anti-static and Fuel/Oil resistant footwear.

Working with electricity? You should consider electrical-resistant footwear.

Working with heat hazards like foundry working or welding? You would need a HRO boot.

Work with Food, in a Medical Lab or Clean Room? You will probably need a safety shoe that is Slip-Resistant, Washable and White.

Are you or your employees Vegan? Serious question. There are Vegan safety trainers, and you might need to consider this if any of your employees are vegans.

The list goes on, but you get the jist.

Get the Correct Size and Fit

it is essential footwear fits your feet properly as you will spend your entire working day in these boots or shoes.

Everybody is different, so it might be that in order to get the right level of protection that fits you properly, you might need to forgo those all singing, all dancing über-boots that impress your mates. Get something more conservative looking, yet correct and safe.

Don't be afraid to invest in some good quality insoles or socks designed to improve your comfort either.

Absolutely NEVER buy second hand safety footwear

Do we really need to explain this?

The only way you can be certain of the history of a piece of safety equipment is buying it new. Buying second hand safety footwear opens you up to so much risk that it is simply not worth it.

You need your toe protection to withstand the 200 Joules it is designed to withstand. If you do not know the history of the footwear, you will not know if that 200 Joules has already been exceeded and the protection rendered useless. Nobody wants to find out there is a broken toe-cap whilst a forklift runs over their foot.

And the price ranges of footwear with differing safety specs really means you have no excuse not to buy new.

Look After Your Footwear and Your Footwear Will Look After You

It is the same with all your PPE to be honest - your foot protection can only take so much abuse before it fails. So the best thing to do is protect your footwear like it protects you. Boots or Shoes will last much longer too, saving you money in the long-run.

- If they get muddy, clean them.

- If they are wet, dry them naturally.

- Use laces properly (don't slip them on and off and stretch them).

- Store them carefully, don't let them rattle around in the back of the van.

- Invest in some Dubbin for leather boots or shoes

And most importantly, if you have an incident where the protection level may have been compromised, CHECK your footwear thoroughly for any failures. If in doubt, replace them immediately.

You need your feet.

- How Long Does PPE Last? (Probably Not As Long As You Think) - 12th March 2025

- BSIF Issues Urgent Warning: 90% of PPE from Non-Registered Providers Fails Safety Tests (2025) - 10th February 2025

- Understanding UK Safety Standards for Respiratory Protection - 14th October 2024