Why Ignoring PPE Maintenance is a Terrible Idea for Your Business

Ignoring PPE maintenance a terrible idea for your business. When safety goes out the window, accidents happen. If accidents happen at work, that means you lose time and money - in the form of worker absence, compensation payouts, and potential fines.

It’s estimated that over 600,000 workers are non-fatally injured at work, often resulting in long absences - but the real figure could be much higher as these accidents often go underreported. Almost 150 workplace fatalities occur each year, but numbers are declining because there are safety measures in place.

Here are some tips on how to perform PPE Maintenance, and how often your company should replace this equipment.

- Page Contents

- Head Protection

- Hearing Protection

- Eye Protection

- Foot Protection

- Hand and Arm Protection

- Respiratory Protection

- Hi Vis Clothing

- Conclusion

Head Protection

Clean

- Clean daily or weekly as needed.

- Clean once a month by soaking in mild soap and hot water for 5-10 minutes and rinse with clean water, wipe, and air dry.

Maintain

- Inspect suspensions before each use.

- Inspect for cracking and gouging (replace immediately if these are found).

- Ultraviolet (UV) exposure, extreme temperatures, chemical exposure, and daily wear can affect the hat’s lifespan.

- Prolonged sunlight exposure can cause flaking and cracking of the shell.

- Chemicals can impact protective measures.

Replace

- Replace hard hats every 5 years (as per manufacturer recommendation).

- Replace internal suspension every 12 months.

- Replace every 2 years if exposed to high temperatures, extreme sunlight, or adverse conditions.

- Replace when cracked or gouged.

- Replace if head protection has sustained impact.

- Replace if head protection is no longer effective.

Hearing Protection

Clean

- To clean hearing protection disassemble ear muffs (not needed for earplugs).

- Wash with mild liquid detergent and rinse in warm water.

- Ensure sound attenuating material inside ear cushions does not get wet.

- Remove skin, oil, and dirt that can harden ear cushions with a soft brush.

- Squeeze excess moisture from ear cushions and place on clean surface to air dry.

- Dispose of disposable earplugs as most cannot be cleaned.

Maintain

- Check hearing protection works effectively, is in good, clean condition, has undamaged seals, headband tension not reduced, has no unofficial modifications, and doesn’t have excess wear and tear.

Replace

- Replace hearing protection when product shows wear and tear.

- Earplugs are no longer pliable.

- Headbands are stretched.

- Ear cushions degraded.

- 6-8 months have passed for normal wear or 3-4 months have passed with heavy use or humid/extreme climates.

- Dispose of disposable ear plugs daily.

Eye Protection

Clean

- Clean daily following manufacturer’s instructions.

- Blow loose dirt and debris from the lenses.

- Rinse under running water (with or without detergent) or use lens cleaning wipes or spray.

- Store in a safe place ( in cases or in any other clean, dry place).

- Avoid rough handling as scratches impair vision and weaken lenses.

Maintain

- Check eye protection for scratches, pits, broken parts, or ill fit.

Replace

- Glasses should be replaced at least every 3 years If Not Used. Every 3 month if used daily.

- Replace damaged, scratched, pitted, broken, bent, or ill-fitting glasses as these do not provide protection.

- Replace damaged parts with original manufacturer parts only to ensure the same safety rating.

Foot Protection

Clean

- Keep clean based on the manufacturing instructions.

- Protect from water damage.

- Wash and dry daily.

- Polish leather footwear and remove debris with a brush.

- Clean soles by brushing and washing air dry - never force dry.

Maintain

- Check footwear for cleanliness, water damage, and debris damage.

Replace

- Replace safety footwear when it’s 6-12 months old, it’s defective, or worn

Hand and Arm Protection

Clean

- Wash/dry (or dispose) of gloves properly.

- Don’t touch contaminated gloves with bare hands.

- Wash hands when taking gloves off.

- Same applies for protective sleeves.

Maintain

- Examine before wear in case of manufacturing defects.

- Extend glove life by washing and rotating gloves.

- Always inspect gloves before use to ensure they are safe.

Replace

- Replace gloves when worn out, torn, heavily soiled, or every day to every three weeks, depending on type of gloves.

- Replace after each use (for disposable gloves) or moving from task to task (either dispose or clean).

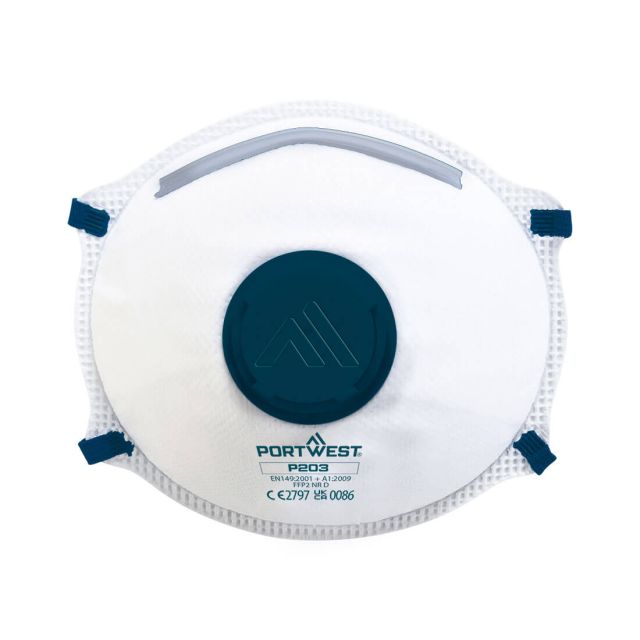

Respiratory Protection

Clean

- Clean and sanitise after each use.

Maintain

- Inspect before each use.

- Record inspection dates, finding, and repairs.

- Emergency use respirators need to be checked monthly for tightness of connection, head straps, valves, tubes, cartridges, canisters, filters, rubber, elastic, and moveable parts for signs of deterioration.

Replace

- Replace respiratory equipment as per manufacturers specified replacement rate / replacement filter rate (daily, weekly, after so much exposure).

- Single use respirators must be disposed of after use or when soiled, damaged, or if it becomes difficult to breathe

Hi Vis Clothing

Clean

- Clean your Hi Vis regularly/daily according to manufacturer instructions.

- Cleaning method will vary for different types of clothing.

Maintain

- Maintain hi vis by repair when possible, or replace if not.

- Employers are responsible for replacing as needed, but well maintained hi vis can last months to years depending on exposure and work environment.

Replace

- Replace hi vis when safety is compromised.

- Check for defects (broken, missing, in need of maintenance, burns, spills, excess soiling, tears, deterioration, etc)

Conclusion

Make sure you create a routine part of the work day (or week) where equipment is checked and maintained otherwise safety could be compromised.

Make sure there is someone (or a team of people) responsible for checking PPE maintenance and replacement.

Keep track of what you buy, when it will likely need replacing, and write down when equipment is cleaned and repaired. When equipment is flagged as ‘needs replacing,’ check over the piece of equipment to see if it still performs safely, and if it doesn’t, replace it.

- How Long Does PPE Last? (Probably Not As Long As You Think) - 12th March 2025

- BSIF Issues Urgent Warning: 90% of PPE from Non-Registered Providers Fails Safety Tests (2025) - 10th February 2025

- Understanding UK Safety Standards for Respiratory Protection - 14th October 2024