How Often Should You Replace Your Hi Vis Clothing?

The frequency of replacing your hi vis clothing is not determined by a period of time, but how it is used and cared for. It doesn't have a shelf-life as such unless it falls under an old hi vis clothing standard.

You've taken the time to research and find the right type of hi vis for you, so it makes financial and safety sense you should know how to look after it.

Having a physical job makes hi vis more susceptible to wear and tear, meaning it needs replacing sooner. If they take care of it, it will not only last longer, it will protect them better.

In this article, we discuss the factors that affect how often you need to replace your Hi Vis clothing.

- Page Contents

- Application

- Maintenance

- Wash Cycle

Application and Use

How you use, care for and store your Hi Vis clothing can alter how often you should replace it. If your job requires physical work in areas where Hi Vis is mandated constantly, you will likely replace it more often than if you drive a vehicle and only put it on when stepping outside your cab.

Having said that, if you hang your vest up behind you in your truck cab, and it sits for most of the day in direct sunlight, you might find it needs replacing much sooner than you thought.

- The factors you should look for are:

- Fading of the fluorescent fabric

- Tears and rips anywhere on the garment

- Worn reflective strip

- No longer visible for 1,000 feet during the day or night

- Pilling (mainly a problem on hi vis fleece jackets)

If your clothing falls under any of these, it will need replacing.

Maintenance of Your Garments

The life cycle of your clothing also depends on how you maintain it. Your Hi Vis needs cleaning when dirty and storing in a dry clean place.

For many applications, you will find you can wipe down your Hi Vis in-between full washes to help get a longer life out of it.

Often, when their hi vis clothing has become dirty, people throw it away.

Low cost Hi Vis vests are the most likely to be binned rather than washed, but you would be wasting money. Most dirt will simply wash out of the polyester it is made from, and so long as you stay within the maximum number of washes (usually 25x), the reflective strip will clean too.

For jobs where you need to remain visible but also presentable, a two-tone garment would come into its own. Two-tone Hi Vis has dark coloured contrast fabric around the areas most likely to become dirty - knees, pockets, waistband, hem cuffs, collar etc - this helps keep the colours bright and the wearer seen. Portwest's PW3 range does this superbly.

Wash Cycle Used

There is a high probability that the tasks you do will make your Hi Vis clothing dirty. It is absolutely crucial that you keep your Hi Vis clean to remain visible to others and keep it compliant.

All EN ISO 20471:2013 compliant high visibility clothing will come with a data specification sheet advising the owner on various issues they should be aware of.

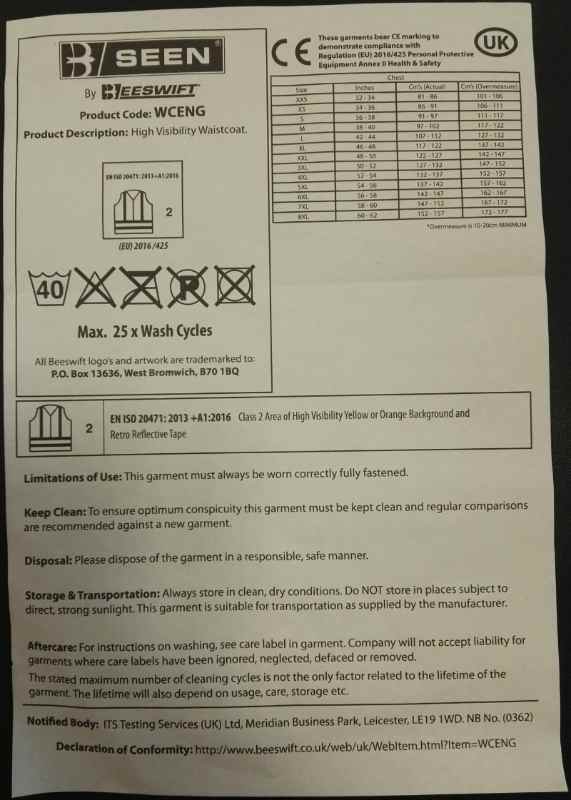

This is a data sheet from Hi Vis manufacturer "Beeswift"

It is important to read the information and guidance provided with your hi vis workwear as it may differ depending on brand or product type.

The data sheet will inform you on how to wash your protective clothing to get the best out of it. For instance the above data sheet tells us to:

- Wash at 40°C

- Do Not Bleach

- Do Not Iron

- Do Not Dry Clean

- Do Not Tumble Dry

And just as important, Wash a MAXIMUM of 25 times. Each time you wash your hi-vis, the reflective strips on the garment loses their quality and will eventually appear blotchy over time. This decreases their effectiveness which can lead to incidents it is designed to protect against.

Stay Protected with XAMAX® Hi Vis Workwear

At XAMAX®, we offer a wide range of hi vis clothing designed to comply with EN ISO 20471 and withstand tough working conditions.

If it's time to replace your workwear, we’ve got a full selection of hi vis garments and other safety gear to suit your needs. Explore more at the XAMAX® homepage and keep your team safe with the best in high-visibility workwear.

As a BSIF Registered Supplier, we’re committed to providing high-quality, durable solutions that help reduce the risk of accidents in the workplace. From hi vis vests and jackets to trousers and fleece jackets, our extensive range caters to all industries.

It is simple to understand when you need to replace your high-visibility clothing. Learn how to maintain it to prolong its life and you will not need to replace it so often.

- How Long Does PPE Last? (Probably Not As Long As You Think) - 12th March 2025

- BSIF Issues Urgent Warning: 90% of PPE from Non-Registered Providers Fails Safety Tests (2025) - 10th February 2025

- Understanding UK Safety Standards for Respiratory Protection - 14th October 2024