Last year we reported on the findings of a BSIF report looking into un-registered retailers selling PPE.

Today, the British Safety Industry Federation (BSIF) has released the results of its latest independent tests (2025), and the findings are nothing short of alarming.

In their comprehensive assessment of personal protective equipment (PPE) procured from non-registered suppliers between December 2023 and December 2024, a staggering 90% of products failed to meet essential safety standards.

A Sharp Rise in PPE Failures

Compared to last year’s report, where 79% of non-member products failed, the situation has worsened significantly. Of the 161 products tested, only 16 met full compliance requirements, leaving 138 products failing critical safety benchmarks. Seven results are still pending, but the trend is already clear—substandard PPE is flooding the UK market.

Key Findings:

- Head Protection (100% failure rate – 6 products): Every helmet tested failed to withstand penetration and shock absorption assessments. This means impacts could break through the outer shell or transfer dangerous force directly to the wearer's head, increasing the risk of traumatic injuries.

- Eye & Face Protection and Fall Protection (100% failure rate – 13 products): None of the tested items provided adequate defence against particle impacts or fall-related stresses. This exposes users to severe risks such as eye injuries from flying debris or catastrophic failure of fall arrest equipment.

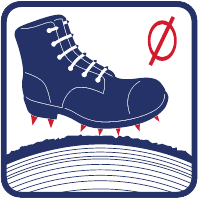

- Safety Footwear (86% failure rate – 31 products): A concerning number of safety shoes, often promoted on platforms like TikTok, failed key safety benchmarks. Issues included poor toecap compression resistance, inadequate protection against impact and midsole penetration, insufficient slip resistance, and failure to meet electrical hazard safety standards.

- Hearing Protection (90% failure rate – 28 products): Deficiencies in cushion and headband pressure compromised the protective seal needed to block hazardous noise levels effectively, leaving wearers vulnerable to long-term hearing damage.

- Safety Gloves (95% failure rate – 21 products): These gloves did not deliver on claims related to cut resistance, abrasion durability, or puncture protection. This dramatically increases the likelihood of hand injuries in hazardous environments.

- Hi-Vis Clothing (85% failure rate – 11 products): Many garments failed chromaticity and luminance tests, meaning they were not bright enough to ensure visibility in low-light conditions. This defeats the primary purpose of hi-vis apparel, which is to keep workers seen and safe.

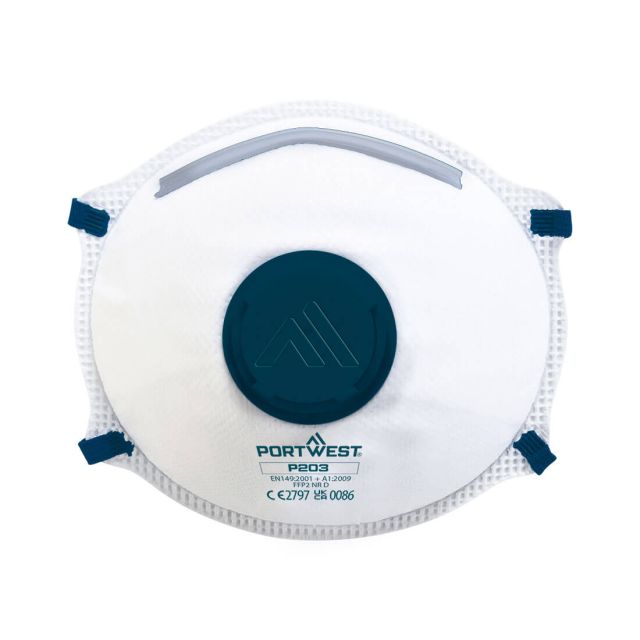

- Respiratory Protective Equipment (RPE) (88% failure rate – 22 products): Tested masks and respirators fell short in filter penetration tests, failing to block hazardous dust and fumes effectively, potentially putting wearers at risk of inhaling dangerous airborne contaminants.

These products failed critical tests, including resistance to impact, compression, abrasion, penetration, and filter effectiveness—posing significant risks to users across industries.

Real Risks Behind the Statistics

Failures weren’t just technicalities; they represented genuine threats to life and limb. From safety helmets unable to withstand impacts to RPE filters that don’t block hazardous dust and fumes, the potential for tragedy is high.

Roy Wilders, BSIF Registered Safety Supplier Scheme Manager, stated:

"The findings are deeply concerning. When protective—and sometimes life-saving—equipment fails to meet standards, it's not just a statistic; it's a potential tragedy waiting to happen."

The Safer Choice: BSIF Registered Safety Suppliers

The contrast with BSIF Registered Safety Suppliers is stark. Of 399 products tested from registered suppliers, 86% passed, and any issues found were promptly rectified. This highlights the effectiveness of stringent quality controls within the BSIF Registered Safety Supplier Scheme.

Alan Murray, BSIF CEO, emphasised:

"Our latest test results have once again brought to light a deluge of problem PPE, from substandard safety helmets to safety shoes that fall a long way short of the required standards for keeping wearers safe. Buyers and specifiers must urgently review their procurement processes and consider what assurances they have that the PPE and safety equipment they are being supplied with is fit for purpose."

Protect Your Workforce: Choose Wisely

When safety is on the line, there's no room for compromise. XAMAX® is proud to be a BSIF Registered Safety Supplier. We only source PPE from trusted, compliant manufacturers and distributors who are also BSIF members. This ensures a secure supply chain, giving you peace of mind that the PPE protecting your team meets the highest UK safety standards.

Always look for the BSIF Registered Safety Supplier shield when purchasing PPE. It’s your assurance of quality, compliance, and commitment to safety.

"Remember, anyone can sell safety, but you shouldn't buy safety from just anyone; always check for the BSIF shield." - BSIF

Final Thought

As these test results show, cutting corners on safety can have dire consequences. Don't take unnecessary risks with your workforce's wellbeing. Trust BSIF Registered Safety Suppliers like XAMAX® to provide PPE that performs when it matters most.

Last year we reported on the findings of a BSIF report looking into un-registered retailers selling PPE. Today, the British Safety Industry Federation (BSIF) has released the results of its latest independent tests (2025), and the findings are nothing short of alarming. In their comprehensive assessment of personal protective equipment (PPE) procured from non-registered suppliers […]

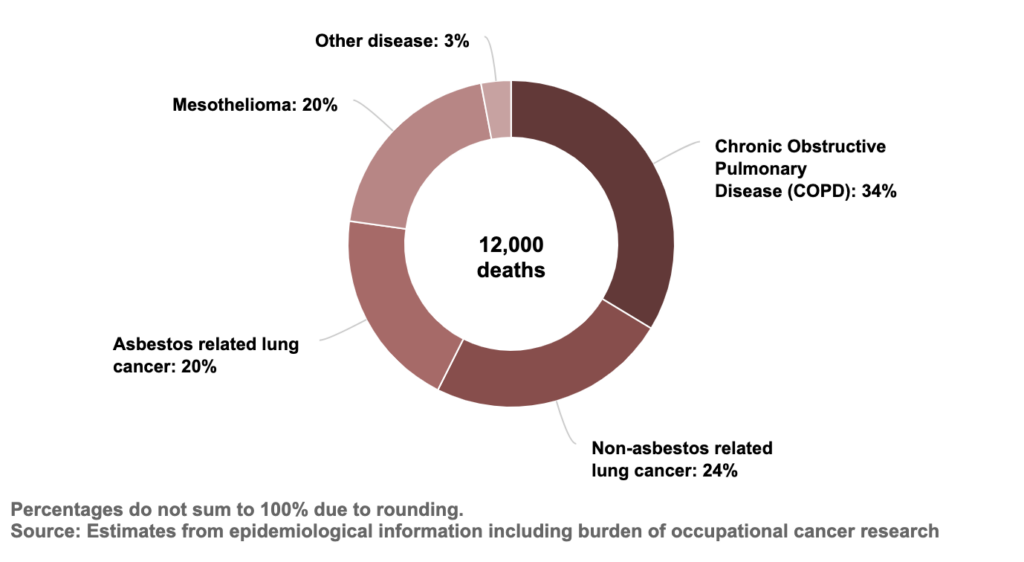

Worker safety is essential in industries where there are hazardous airborne particles, chemicals, or gases. Respiratory Protective Equipment (RPE) is crucial for protecting workers from respiratory diseases and long-term health issues. In the United Kingdom, various rules provide clear principles that ensure that workers are adequately protected.

This guide gives a full review of the UK respiratory protection safety requirements, with an emphasis on the legal framework and how to choose the appropriate RPE for your staff.

- Page Contents

- The Legal Framework

- Respiratory Protective Equipment (RPE) Standards

- Choosing the Right Respiratory Protection

- XAMAX®: Your Partner in Respiratory Protection

- Conclusion

The Legal Framework

The legal framework for respiratory protection in the UK is built on a set of regulations intended to ensure worker safety and correct usage of Personal Protective Equipment (PPE).

These regulations require that both companies and employees follow specific guidelines for selecting, using, and maintaining RPE.

Control of Substances Hazardous to Health (CoSHH) Regulations 2002

CoSHH is one of the most important regulations for workplace health and safety. It applies to all organisations where hazardous substances are used. These include protection against chemicals, dust, and fumes, which can harm workers' health if inhaled.

Under CoSHH, employers must do the following:

- Identify what hazardous substances are present in the workplace.

- Assess the risks associated with these substances.

- Control exposure by using the right protective measures, including providing RPE (respiratory protective equipment) to employees.

- Ensure workers are trained to use the equipment properly.

Personal Protective Equipment (PPE) at Work Regulations 1992

The PPE at Work Regulations 1992 require employers to provide suitable protective equipment whenever there are risks to workers' health and safety. For respiratory protection, this means providing the correct RPE based on the hazards identified in the workplace.

Employers must ensure that:

- The RPE provided is appropriate for the type of work and level of risk.

- The equipment is well-maintained and clean.

- Workers are trained to use and care for their RPE properly.

The Management of Health and Safety at Work Regulations 1999

This regulation requires employers to carry out risk assessments for health and safety hazards. It ensures that protective measures are in place and that workers are given the right equipment, training, and supervision.

For respiratory protection, this means:

- Employers must regularly review and update their risk assessments to make sure the right RPE is in use.

- They must train workers on the correct use of RPE and keep an eye on the equipment's condition.

Respiratory Protective Equipment (RPE) Standards

RPE must meet specific UK and European standards. The most common standard is EN 149 for disposable filtering facepieces, which provides three levels of protection: FFP1, FFP2, and FFP3.

- FFP1 masks provide the least protection and are suitable for low levels of dust.

- FFP2 masks offer moderate protection against dust, mists, and fumes.

- FFP3 masks give the highest protection and are often used in more dangerous environments with high levels of harmful dust and particles.

There are also half-face and full-face respirators that must meet EN 140 and EN 136 standards. These provide higher levels of protection and can be fitted with different types of filters based on the substances in the air.

Choosing the Right Respiratory Protection

Choosing the right RPE depends on the risks in the workplace. Employers need to consider factors like the type of substance, how much of it is in the air, and how long the worker will be exposed to it. It's important to choose equipment that fits well and is comfortable for the wearer to ensure they use it correctly.

Workers must also be trained in how to wear and care for their RPE to keep it working properly. For example, a dust mask that doesn’t fit properly won’t give full protection, so fit-testing is essential.

XAMAX®: Your Partner in Respiratory Protection

XAMAX® recognise the importance of providing suitable respiratory protection for your employees. As a BSIF Registered Safety Supplier, we ensure that all of our RPE meets UK safety standards, giving you confidence that your workforce is safe.

We supply a wide range of RPE, from disposable masks to full-face respirators, ensuring that we have a solution for most sectors and risk levels. Our friendly staff can assist you in choosing the right equipment for your requirements, and this blog provides guidance on maintenance and care to make sure your RPE remains in perfect working order.

When you use XAMAX®, you're buying more than just high-quality safety equipment; you also get professional assistance to keep your workers safe.

Conclusion

Knowing and complying to the UK safety regulations for respiratory protection is vital for protecting your employees from dangerous dust, fumes, and gases.

Employers need to conduct regular risk assessments, supply suitable RPE, and ensure employees receive training in its use.

Whether you’re working with low levels of dust or dangerous chemicals, the correct respiratory protection is key to preventing serious health issues.

If you need help choosing the right RPE, XAMAX® is here to support you with our wide range of high-quality products and expert advice.

Worker safety is essential in industries where there are hazardous airborne particles, chemicals, or gases. Respiratory Protective Equipment (RPE) is crucial for protecting workers from respiratory diseases and long-term health issues. In the United Kingdom, various rules provide clear principles that ensure that workers are adequately protected. This guide gives a full review of the […]

A key element of workplace safety is respiratory protection, especially in sectors where employees are exposed to hazardous airborne particles. Wearing the right respiratory protection equipment (RPE) is essential to preventing major respiratory illnesses associated with everything from dust in construction to hazardous substances in manufacturing.

The most significant regulations, classifications, and applications of respiratory protection in many sectors are covered in this guide, giving workers and managers the knowledge they need to ensure a safe work environment.

- Page Contents

- Introduction to Respiratory Protection

- Key UK Regulations for Respiratory Protection

- Types of Respiratory Protection

- Respiratory Protection Ratings Explained

- Applications by Industry

- XAMAX®: Why Choose Us?

- Conclusion

Introduction to Respiratory Protection

Respiratory Protective Equipment (RPE) is essential in workplaces where employees are exposed to airborne hazards such dust, fumes, vapours, and gases.

Proper RPE use can help to prevent long-term health issues such as chronic respiratory diseases, lung cancer, and other major disorders.

Workers and employers can ensure effective protection in any hazardous environment by understanding the relevant legislation and protective ratings.

Key UK Regulations for Respiratory Protection

Several regulations govern the use of respiratory protection in the UK. Employers must comply with these rules to ensure the safety of their workers.

Control of Substances Hazardous to Health (COSHH) Regulations

The COSHH Regulations 2002 are one of the most important frameworks that require employers to control exposure to hazardous substances in the workplace. According to COSHH, employers must:

- Assess the risks: Identify the hazardous substances and evaluate the level of exposure.

- Provide adequate RPE: Ensure that the provided respiratory protection is suitable for the work environment.

- Conduct face fit testing: Tight-fitting respirators must be tested for a proper seal on each employee's face.

- Monitor health: Regular health surveillance is required for workers who may develop lung diseases.

Personal Protective Equipment at Work Regulations 1992

The PPE at Work Regulations 1992 mandate that employers must provide suitable personal protective equipment, including RPE, at no cost to the employee. These regulations also require employers to:

- Ensure that PPE is appropriate for the risks involved.

- Maintain and replace the equipment regularly.

- Train employees on the correct usage and limitations of RPE.

British Standards Institution (BSI) Compliance

BSI is responsible for setting standards for the design and testing of PPE. Respiratory protection must comply with BS EN 149, the UK standard for filtering facepieces (FFP), and other relevant standards.

Employers should ensure that all RPE is certified by BSI for protection against specific hazards.

Fit2Fit Accreditation for Face Fit Testing

The Fit2Fit accreditation ensures that those performing face fit tests for tight-fitting respirators are competent. Testing ensures the mask properly seals to the wearer’s face, reducing the risk of inhaling contaminants.

Types of Respiratory Protection

There are several types of RPE, each suited for different hazards and industries. Choosing the right one depends on the level of airborne hazard and the type of work performed.

Disposable Dust Masks

These masks, also known as filtering facepieces (FFP), provide protection against dust and non-toxic particles. They are common in construction and light industrial work where low-level dust exposure occurs.

Materials: Typically made from lightweight fabric with integrated particulate filters.

Half-Face Respirators

Half-face respirators cover the nose and mouth, offering protection against dust, fumes, vapours, and some gases. These are suitable for industries dealing with more hazardous airborne particles, such as metalworking or chemical processing.

Materials: Made from silicone or rubber for durability, with replaceable filters.

Full-Face Respirators

Full-face respirators provide a higher level of protection, covering the entire face to protect both the respiratory system and the eyes from exposure to harmful substances. Commonly used in hazardous environments such as chemical plants.

Materials: Made from durable rubber or silicone with replaceable filters.

Powered Air-Purifying Respirators (PAPR)

PAPRs use a battery-powered fan to draw air through filters. These are often used in environments where workers are exposed to toxic fumes, dust, or vapours for extended periods.

Materials: Lightweight and designed for long-term use with advanced filtration systems.

Self-Contained Breathing Apparatus (SCBA)

SCBAs provide breathable air from a tank and are used in environments with little or no oxygen, such as confined spaces or emergency response situations.

Materials: High-strength materials to withstand extreme conditions.

Respiratory Protection Ratings Explained

The level of protection provided by respiratory equipment is measured using specific ratings and assigned protection factors (APF).

FFP1, FFP2, and FFP3 Ratings

These ratings apply to filtering facepieces and represent the level of protection they offer against particulate hazards:

- FFP1: Filters at least 80% of airborne particles. Suitable for light dust environments, such as basic construction tasks.

- FFP2: Filters at least 94% of airborne particles. Suitable for environments with moderate hazards, such as sanding and plastering.

- FFP3: Filters at least 99% of airborne particles. Recommended for high-hazard environments, such as working with asbestos or toxic chemical fumes.

APF (Assigned Protection Factor)

The Assigned Protection Factor (APF) is an important measure for determining the amount of protection provided by respiratory protective equipment (RPE). APF ratings indicate how well the respirator reduces exposure to hazardous substances when worn correctly. The higher the APF, the more effective the protection.

For example, an APF of 10 means that the respirator reduces the user’s exposure to airborne contaminants to 1/10th of the concentration in the surrounding air. An APF of 20 reduces it to 1/20th, and so on. Knowing the APF of a respirator allows employers and workers to make informed decisions about whether the equipment is suitable for the level of hazards present in the workplace.

In the UK, the Health and Safety Executive (HSE) provides guidelines on selecting respirators with appropriate APF levels for different hazardous environments. Different types of RPE, such as filtering facepieces, half masks, and full-face masks, all have varying APF values. It's essential to refer to these ratings when assessing the suitability of respiratory protection for specific tasks.

Applications by Industry

Different industries require different types of respiratory protection depending on the specific hazards present. Here’s a breakdown of common industries and the type of respiratory protection needed:

Construction

Construction workers are often exposed to dust, fumes, and other airborne particles from materials like concrete, brick, and asbestos. FFP3 masks are typically required to protect against these hazards.

Regular fit testing and maintenance are critical to ensure continued protection.

Manufacturing

In industries like metalworking, painting, and chemical processing, workers may be exposed to hazardous fumes and vapours.

Half-face and full-face respirators with appropriate filters are essential to protect workers from harmful gases and chemicals.

Agriculture

Farmers and agricultural workers face risks from dust, pesticides, and animal dander. Disposable FFP2 or FFP3 masks are often used to protect against these particulates, while half-face respirators are useful for chemical applications.

Automotive and Engineering

Workers in automotive repair and engineering are often exposed to dust, solvents, and other chemicals.

Half-face respirators with P2 or P3 filters offer effective protection from inhaling dangerous fumes and particles during tasks such as sanding, welding, and painting.

Mining and Quarrying

Workers in the mining industry are exposed to high levels of dust and sometimes toxic gases. Full-face respirators and PAPRs are commonly used to provide sufficient protection in these hazardous environments.

Woodworking

In woodworking, wood dust is the primary hazard. FFP2 or FFP3 dust masks provide essential protection for workers cutting, sanding, or shaping wood, as these tasks generate fine particulate matter that can be harmful to the lungs.

XAMAX®: Why Choose Us?

When it comes to respiratory protection, you can trust XAMAX® to supply the highest quality PPE that meets UK safety standards.

As a BSIF registered safety supplier, we ensure that every product complies with regulations and is designed to provide maximum protection for your workforce.

Whether you're in construction, manufacturing, or any other industry, XAMAX® offers a wide range of respiratory protection to suit your specific needs.

Protect your team with our industry-leading respiratory protective equipment. Explore our full range of RPE or request a callback for expert guidance on choosing the right RPE for your business.

Conclusion

Respiratory protection is a crucial part of workplace safety, especially in sectors where workers are exposed to air-borne contaminants like dust, fumes, vapours, or gases. Understanding the many forms of RPE, regulatory demands, and appropriate protection ratings enables companies and employees to make educated decisions about their safety.

Employers must comply with requirements set by UK legislation such as COSHH and PPE at Work in order provide proper protection to their employees. Companies can significantly reduce the risk of respiratory infections among their employees by selecting the appropriate respirator, conducting face fit tests, and ensuring regular maintenance.

Whether you need basic dust masks for light construction or advanced PAPRs for chemical plants, selecting the correct RPE is crucial for worker health and safety. Always ensure that your equipment complies with the highest safety standards and is suited for your industry’s specific needs.

XAMAX® are committed to providing BSIF-certified respiratory protection products that meet UK safety standards. Our range includes everything from disposable masks to full-face respirators, ensuring that you have the right protection for any job.

A key element of workplace safety is respiratory protection, especially in sectors where employees are exposed to hazardous airborne particles. Wearing the right respiratory protection equipment (RPE) is essential to preventing major respiratory illnesses associated with everything from dust in construction to hazardous substances in manufacturing. The most significant regulations, classifications, and applications of respiratory […]

The safety footwear requirements were considerably updated in 2022, most notably in the EN ISO 20345:2022 and EN ISO 20347:2022 standards. These changes reflect major advances in ensuring worker safety across a variety of sectors. Understanding these developments is critical for employers, organisations, and individuals responsible for workplace safety to maintain compliance and protect employees' well-being.

This article will walk you through the important changes to safety footwear regulations, how they affect both employers and employees, and how to make sure your footwear meets the most recent standards.

- Page Contents

- Overview of the 2022 Safety Footwear Standards

- Types of Footwear Covered by the 2022 Standards

- Key UK Regulations for Safety Footwear

- Key Changes in EN ISO 20345:2022 and EN ISO 20347:2022

- New Markings and Marking Changes

- How to Ensure Compliance with the New Standards

- Applications by Industry

- Why Choose XAMAX® for Your Safety Footwear?

- Conclusion

Overview of the 2022 Safety Footwear Standards

The EN ISO 20345 and EN ISO 20347 standards are essential to establishing the minimum requirements for safety footwear. They encompass everything from protection features to testing regulations, ensuring that industrial footwear minimises worker injuries.

The EN ISO 20345:2022 standard is largely applicable to footwear designed to provide protection in high-risk areas (such as construction and engineering). EN ISO 20347:2022, on the other hand, focusses on occupational footwear in which high-level protection (such as toe caps) is optional but some protection (such as slip resistance) is necessary.

Here are the most significant modifications in these standards from the previous editions (EN ISO 20345:2011 and EN ISO 20347:2012):

Types of Footwear Covered by the 2022 Standards

- Safety Boots: Footwear designed for industries with a high risk of impact or compression injuries, such as construction, manufacturing, and mining.

- Safety Shoes: Typically used in lower-risk environments like warehousing, these offer toe protection and slip resistance.

- Safety Trainers: Lightweight footwear ideal for roles where mobility is key, such as in logistics or maintenance.

- Wellington Boots: Provide protection in wet or chemical-heavy environments like agriculture or fisheries, with resistance to liquids and chemicals.

Each type of footwear must meet specific EN ISO 20345:2022 or EN ISO 20347:2022 ratings depending on the work environment.

Key UK Regulations for Safety Footwear

Employers must provide personal protection equipment (PPE) such as safety footwear to employees who are exposed to health or safety dangers, according to UK legislation. Among these are the Personal Protective Equipment at Work Regulations of 1992, which align to European standards and stipulate that employers ensure that PPE is suitable, well-maintained, and provided at no charge when required.

With the 2022 updates, UK safety standards now reflect the following changes in PPE footwear:

Key Changes in EN ISO 20345:2022 and EN ISO 20347:2022

New Classification for Slip Resistance: The new standards provide enhanced guidelines for slip resistance, now a mandatory requirement for all certified footwear. Testing on both ceramic tiles (SRA) and steel plates with glycerol (SRB) is included to simulate various working environments. Footwear must pass tests for both to meet the SRC designation, which applies to all high-slip risk industries.

Breathability and Comfort: Worker comfort has been emphasised in the latest regulations. The EN ISO 20345:2022 standard includes improved guidelines on breathability, moisture management, and overall comfort, making long shifts in safety boots more manageable, reducing fatigue, and increasing worker productivity.

Impact Resistance of Toe Caps: Toe caps must still withstand a 200-Joule impact (equivalent to dropping a 20 kg weight from a height of 1 meter). However, composite toe caps (made from non-metal materials) are now more widely tested under varying temperatures, ensuring that safety boots perform equally well in extreme hot or cold conditions.

Penetration Resistance: Footwear must meet updated penetration resistance standards, ensuring that soles protect against sharp objects in industrial settings. Composite and steel midsole protections must undergo strict testing to prevent penetration by sharp objects like nails, glass, or debris on site. This is particularly relevant for construction and demolition industries.

Electrical and Anti-Static Properties: In high-risk sectors like electronics and energy, regulations for electrical resistance and anti-static properties have been tightened. The new standards now include more stringent tests to ensure footwear protects against electrostatic discharge (ESD) or electrical shocks.

Heat and Cold Resistance: The EN ISO 20345:2022 standard now provides more detailed guidelines on the HI (heat insulation) and CI (cold insulation) ratings, ensuring footwear can withstand a range of environmental conditions. This is especially relevant for industries such as welding, foundries, and outdoor work.

Sustainability and Materials: The 2022 standards emphasise sustainability, encouraging manufacturers to use eco-friendly and recyclable materials while maintaining high levels of protection. This focus is a reflection of the industry's drive towards more sustainable manufacturing practices.

New Markings and Marking Changes

With regulation changes comes new safety claims and new markings to suit the advancements in safety footwear technology:

| Icon | Description |

|---|---|

| FO (Fuel Oil Resistance): This marking indicates that the outsole material has been tested for resistance to fuel oils. This is no longer part of the Shortcut codes and must be marked separatley |

| P (Penetration Resistance) is now split across 3 codes: P - Perforation resistance metallic. Resistance to sole perforation of nails and sharp objects. Incorporating a metallic perforation resistant insert. PL - Perforation resistance non-metallic (LARGE). Resistance to perforation of nails. Incorporating a non-metallic Perforation resistant insert, tested with a 4.5mm test nail. For general end use where nails may be present. PS - Perforation resistance non-metallic (SMALL). Resistance to perforation of nails. Incorporating a non-metallic Perforation resistant insert, tested with a 3mm test nail. Intended for specialist uses where there is a higher likelyhood of encountering nails or likelyhood of encountering narrower nails. |

| C (Partially Conductive). The terminology has been changed from “Conductive”, to prevent confusion with claims associated with live electrical working. |

| SRA, SRB, SRC (Slip Resistance Ratings) are not mandatory. Slip resistance on tiled floor surface with Sodium Lauryl sulphate (soapy water) lubricant, tested at both the heel and forepart. No additional marking is applied. SR - Slip resistance on the tiled floor surface with glycerol lubricant, tested at both the heel and forepart. The steel floor surface is no longer used in testing. Ø - Slip resistance properties have not been achieved but the outsole includes specialist features such as spikes for logging or heavy cleats for use in soft and loose ground. |

| WPA (Water Resistance): Formerly "WRU" indicates that the footwear has water-resistant uppers, meaning the material used for the upper part of the footwear can resist water penetration. This feature is important for workers in wet or damp environments, such as those in outdoor construction or maintenance roles, where keeping the feet dry is critical to avoid discomfort and potential health risks such as trench foot. |

| LG - A new safety claim "ladder grip" indicates that the sole is designed with patterning in the waist area to conform to the rungs of a ladder. |

| SC - A new claim "Scuff cap" indicates that the footwear includes an additional overlay material in the toe area offering abrasion resistance during kneeling activities. |

How to Ensure Compliance with the New Standards

Employers should review their current stock of safety footwear and ensure that it complies with the EN ISO 20345:2022 or EN ISO 20347:2022 standards.

Footwear should be inspected regularly for wear and tear, and employees should be trained to understand the importance of choosing footwear based on the specific hazards they face on-site.

Applications by Industry

The updates to these standards are designed to address industry-specific risks:

- Construction: Focus on impact and penetration resistance, ensuring that all footwear meets S3 standards with toe cap protection and penetration resistance.

- Engineering: Higher standards for electrical resistance and protection against sharp objects, with composite and steel options now more rigorously tested.

- Logistics and Warehousing: Emphasis on slip resistance and lightweight comfort, with composite toe caps offering protection without the bulk of steel.

- Agriculture and Fisheries: Increased focus on waterproofing, chemical resistance, and thermal insulation to protect workers in wet environments.

Why Choose XAMAX® for Your Safety Footwear?

As a BSiF Registered Safety Supplier, XAMAX® ensures that every pair of safety footwear we supply complies with the latest UK and European standards. We pride ourselves on providing safety boots, shoes, and trainers that meet or exceed the EN ISO 20345:2022 and EN ISO 20347:2022 standards, so your team gets maximum protection in any work environment.

Whether you need steel toe caps for heavy industry or lightweight composite safety trainers for logistics, we have the perfect solution for your workforce.

Browse our range of compliant safety footwear or contact our team to discuss your PPE needs.

Conclusion

The 2022 updates to safety footwear regulations bring essential changes to protect workers across various industries.

By understanding the requirements of EN ISO 20345:2022 and EN ISO 20347:2022, you can ensure that your safety footwear meets the latest standards, providing maximum protection and comfort.

From improved slip resistance to more stringent electrical safety standards, these updates highlight the importance of choosing the right footwear for the job.

Stay compliant, protect your workers, and choose XAMAX® for all your safety footwear needs.

The safety footwear requirements were considerably updated in 2022, most notably in the EN ISO 20345:2022 and EN ISO 20347:2022 standards. These changes reflect major advances in ensuring worker safety across a variety of sectors. Understanding these developments is critical for employers, organisations, and individuals responsible for workplace safety to maintain compliance and protect employees’ […]

Safety footwear is crucial for protecting workers from injuries at work, particularly in high-risk industries such as construction, engineering, and manufacturing. In the UK, strict safety standards exist to ensure footwear meets specific criteria for protection.

This article covers the key standards and safety ratings that determine whether footwear is safe to wear in the workplace and conforms with UK legislation.

- Page Contents

- The Importance of UK Safety Standards for Footwear

- Key UK Regulations for Safety Footwear

- Key Requirements of UK Safety Footwear Regulations

- Testing and Certification for Compliance

- XAMAX®: Your Trusted Partner for Safety Footwear

- Conclusion

The Importance of UK Safety Standards for Footwear

UK law is very clear when it comes to worker safety. The right footwear can prevent injuries that might otherwise result in lost time at work, long-term health problems, or even worse.

Safety boots are designed to protect workers from common hazards, such as heavy objects, sharp materials, and slippery floors. To ensure the right level of protection, the UK enforces certain safety standards for work boots and shoes.

Key UK Regulations for Safety Footwear

EN ISO 20345:2011

This is the main safety footwear standard in the UK, and it applies to all safety boots and shoes.

It says that footwear should protect the toes from impact (with a minimum 200-joule protection level), prevent foot punctures, and meet other specific requirements based on the workplace environment. This standard ensures that footwear provides a basic level of protection that is consistent across industries.

Personal Protective Equipment at Work Regulations 1992 (PPEWR 1992)

According to this regulation, employers must give their workers proper PPE, including safety footwear, without charge, when there are risks to health or safety in the workplace.

The footwear must be appropriate for the task at hand, properly fit the wearer, and provide enough protection for the hazards they face.

BSI (British Standards Institution) Compliance

The British Standards Institution (BSI) sets the bar for quality in the UK, and when it comes to safety footwear, BSI works with manufacturers to make sure the products meet required safety standards.

BSI compliance means that safety footwear has been independently tested and certified, giving employers peace of mind that the footwear meets safety regulations.

HSE Guidelines

The Health and Safety Executive (HSE) is the body responsible for enforcing workplace safety laws in the UK. HSE provides guidelines to help employers choose and provide the right safety footwear for their workers.

They also check that businesses are following the rules, conducting inspections, and investigating incidents. Failure to meet HSE standards can lead to fines or prosecution, so it’s essential to follow their advice.

Key Requirements of UK Safety Footwear Regulations

UK safety footwear regulations are strict about the level of protection safety boots must offer. The following are the key features required by law:

- Toe Protection (200-Joule Impact): Safety footwear that has toe protection must withstand the impact of 200 joules. That’s roughly the same as a heavy object, like a hammer or a brick, falling from height onto the foot. Any footwear with toe caps must meet this requirement.

- Slip Resistance: Footwear must also be slip-resistant to prevent accidents on surfaces like tiles, wet steel, or greasy floors. There are three ratings for slip resistance: SRA, SRB, and SRC, with SRC being the highest rating. Employers must select the right level of slip resistance depending on the workplace environment.

- Penetration Resistance: To prevent injuries from sharp objects, some safety boots have penetration-resistant midsoles. This feature is important on construction sites or anywhere with nails, scrap metal, or sharp tools on the floor.

- Water Resistance: In industries where workers are exposed to wet conditions, safety footwear must provide water resistance. This protects workers from discomfort and health problems caused by wet feet.

- Heat and Cold Insulation: Some work environments require extra protection from extreme temperatures. Footwear with heat or cold insulation (marked as "HI" for heat and "CI" for cold) helps keep workers comfortable and safe.

- Fuel and Oil Resistance: For workers in industries like automotive or chemical processing, the soles of their footwear need to resist fuel, oil, and other harmful chemicals. Boots marked with "FO" provide this type of resistance.

- Electrical Resistance: Workers exposed to electrical hazards need safety footwear that protects against electrical shock. Boots marked "I" (for insulation) or "ESD" (Electrostatic Discharge) are designed to prevent the buildup of static electricity or shield workers from electric shock.

You can learn more about the specific safety footwear ratings and codes associated with them in our Guide to Safety Footwear Ratings.

Testing and Certification for Compliance

Before any safety footwear can be sold in the UK, it must be rigorously tested to meet the requirements of EN ISO 20345:2011. Once a pair of boots has passed these tests, they are given a CE mark, proving that they meet all European safety standards.

In addition, buying from a BSiF Registered Safety Supplier ensures that the safety boots you purchase come from a trusted source, giving you the reassurance that they are compliant with UK regulations.

XAMAX®: Your Trusted Partner for Safety Footwear

When it comes to choosing safety footwear, compliance with UK safety standards is non-negotiable. As a BSiF Registered Safety Supplier, XAMAX® supplies only high-quality, certified footwear that meets EN ISO 20345:2011 standards.

Our range includes everything from steel-toe boots to waterproof wellingtons, ensuring protection across various industries. We work closely with our customers to provide footwear solutions that fit specific job requirements, always focusing on both safety and comfort.

We pride ourselves on being more than just a PPE supplier. We're a trusted partner that helps businesses protect their workers by offering a wide range of compliant safety footwear.

Conclusion

Understanding the UK safety standards for protective footwear is crucial for businesses and workers alike.

From preventing foot injuries to protecting against slips, sharp objects, and electric hazards, safety boots are a must in many workplaces.

By ensuring compliance with UK regulations and choosing the right protection levels, employers can create a safer work environment and reduce the risk of accidents.

XAMAX® provides reliable, compliant safety footwear to businesses across all industries. Choose us for your PPE needs, and rest assured that your team is equipped with the best.

Safety footwear is crucial for protecting workers from injuries at work, particularly in high-risk industries such as construction, engineering, and manufacturing. In the UK, strict safety standards exist to ensure footwear meets specific criteria for protection. This article covers the key standards and safety ratings that determine whether footwear is safe to wear in the workplace and […]

A PPE compliance audit for safety footwear is a must to ensure that all safety shoes, boots, trainers, and other protective footwear on site comply with the relevant regulations and meet workplace safety standards.

Because safety footwear is such a crucial part of personal protective equipment (PPE), carrying out regular audits helps uncover potential issues before they lead to accidents, protects workers, and ensures your company complies with UK health and safety regulations.

In this step-by-step (pun intended) guide, we'll walk you through (pun also intended) the basics of performing an audit for your workplace's safety footwear.

- Page Contents

- Step 1: Review Safety Footwear Regulations and Standards

- Step 2: Audit Safety Footwear Types and Applications

- Step 3: Inspect Safety Footwear Condition and Usage

- Step 4: Evaluate Supplier Certifications and Quality Assurance

- Step 5: Document Non-Compliance and Set Corrective Actions

- Why Choose XAMAX® for Your Safety Footwear?

- Conclusion

Step 1: Review Safety Footwear Regulations and Standards

Personal Protective Equipment at Work Regulations 1992

Employers are required to provide appropriate PPE, including safety footwear, at no cost to employees. The footwear must meet the standards outlined in EN ISO 20345:2011, which requires toe protection capable of withstanding 200 joules of impact.

BSI Compliance

The British Standards Institution (BSI) certifies safety footwear in the UK, ensuring compliance with BS EN ISO 20345:2011 for impact resistance, penetration resistance, and slip resistance.

HSE Guidelines

The Health and Safety Executive (HSE) outlines guidelines for PPE in the workplace. Employers must ensure that footwear provides the necessary protection against specific risks like electrical hazards, chemical exposure, slips and trips, or sharp objects.

Step 2: Audit Safety Footwear Types and Applications

During the audit, verify that the type of safety footwear provided matches the specific risks within your industry, workplace, and specific tasks. For example:

- Construction and Engineering: Workers should have boots with midsole penetration resistance, ankle support, and toe caps that protect against heavy objects and punctures.

- Food and Medical Sectors: Safety wellingtons or clogs with slip resistance, waterproofing, and easy-clean materials are essential.

- Manufacturing and Warehousing: Safety trainers with anti-slip soles, steel or composite toe caps, and electrical hazard protection should be considered.

Make sure each footwear type complies with EN ISO 20345:2011 and carries the necessary ratings such as S1, S2, S3 (which includes midsole protection) or SRC (slip resistance) depending on the work environment and job tasks.

Step 3: Inspect Safety Footwear Condition and Usage

A key part of this compliance audit is ensuring that footwear is in good condition and is being used appropriately. Inspect each pair for:

- Toe Cap Integrity: Ensure no visible dents or signs of failure in the toe cap.

- Sole Condition: Check for excessive wear in the sole, including cracks, tears, or loss of tread. Damaged soles compromise slip resistance and protection from sharp objects.

- Fit and Comfort: Confirm that employees have footwear that fits properly. Ill-fitting boots can cause discomfort and increase the likelihood of accidents due to tripping.

- Regular Replacement: Footwear should be replaced every 6 to 12 months depending on wear and tear, even if it still appears intact.

Step 4: Evaluate Supplier Certifications and Quality Assurance

For proper compliance and traceability, footwear should be supplied by a BSIF Registered Safety Supplier. Work with certified suppliers, such as XAMAX®, to make sure that every safety footwear meets EN standards and reliably has features like penetration resistance, anti-static qualities, and heat protection.

Choosing a trustworthy supplier ensures that those items have been carefully tested and approved for safety in the workplace.

Step 5: Document Non-Compliance and Set Corrective Actions

If any non-compliance issues are uncovered during the audit (such as missing ratings, damaged footwear, or inappropriate types), document these findings and create a corrective action plan. This might include:

- Replacing old or damaged footwear immediately.

- Providing additional training to staff on how to inspect and care for their footwear.

- Ensuring regular monitoring of the condition of safety footwear to catch issues early.

Compliance audits should be conducted at regular intervals (e.g., annually) or whenever significant changes to workplace conditions occur.

Why Choose XAMAX® for Your Safety Footwear?

XAMAX® is a trusted BSIF Registered Safety Supplier, which means all our safety footwear meets the highest industry standards and complies with EN ISO 20345:2011. Whether you need safety boots, trainers, or wellingtons, XAMAX® provides footwear that’s both durable and comfortable, tailored to your industry’s specific needs.

Choosing XAMAX® gives you peace of mind knowing that your workers are fully protected, while you remain compliant with UK safety regulations. Contact us for expert advice on how to keep your workforce safe.

Conclusion

Conducting a PPE Compliance Audit for Safety Footwear is a critical phase in ensuring your workforce's safety and protection while adhering to UK regulations.

Regular audits not only help to identify risks and potential noncompliance, but they also help establish a safety culture in the workplace.

Businesses could dramatically reduce their risk of workplace injuries by reviewing applicable legislation, checking the quality of safety footwear, and ensuring that proper footwear is worn for any given tasks.

Partnering with trustworthy suppliers like XAMAX®, who are fully compliant with BSI standards, ensures that your workers will be supplied with high-quality, certified safety footwear.

By remaining proactive and paying attention to PPE compliance, your organisation can avoid penalties, reduce workplace accidents, and promote a healthy, productive workplace.

Get In Touch - We're Here To Help

A PPE compliance audit for safety footwear is a must to ensure that all safety shoes, boots, trainers, and other protective footwear on site comply with the relevant regulations and meet workplace safety standards. Because safety footwear is such a crucial part of personal protective equipment (PPE), carrying out regular audits helps uncover potential issues before they […]

Safety footwear is essential for preventing workplace foot injuries and complying with UK regulations. Understanding the legal obligations, safety ratings, and industry-specific applications helps companies to provide the right level of safety to their employees.

This guide covers all you need to know about selecting, using, and maintaining safety footwear.

- Page Contents

- Introduction to Safety Footwear

- UK Safety Footwear Regulations

- Key Safety Footwear Ratings and Standards

- The Importance of Slip Resistance in Safety Footwear

- Industry-Specific Applications of Safety Footwear

- How to Select the Right Safety Footwear

- Proper Care and Maintenance of Safety Footwear

- Why Choose XAMAX® for Your Safety Footwear Needs

- Conclusion

Introduction to Safety Footwear

Safety footwear is a crucial part of Personal Protective Equipment (PPE) in a range of industries, including construction, manufacturing, logistics, and food services.

The correct footwear protects workers from multiple hazards such as sharp objects, falling materials, chemicals, electrical shocks, and so on.

Employers in the United Kingdom are legally obliged to provide safety footwear when a risk assessment identifies the need for it.

Wearing the correct safety footwear, whether to protect against foot injuries, slips, or dangerous substances, can help prevent serious accidents and ensure worker safety.

UK Safety Footwear Regulations

In the United Kingdom, the primary regulations governing safety footwear are the Personal Protective Equipment at Work Regulations 1992, as amended in 2011 and 2016, and the EN ISO 20345:2011 standard. These regulations provide the standard for ensuring that safety footwear provides suitable protection to workers.

Key Requirements Include:

- Toe Cap Protection (Where Applicable): Safety footwear with toe caps must offer protection against a 200-joule impact. This is a crucial requirement for footwear used in environments with risks of falling or heavy objects, ensuring the toes are adequately protected. Not all safety footwear has toe caps, but those that do must meet this standard.

- Slip Resistance: Footwear must meet minimum standards for slip resistance to prevent slips and falls in various work environments. This is tested under conditions outlined by SRA, SRB, and SRC standards, depending on the surface type (ceramic or steel) and lubrication (soapy water or glycerol).

- Markings and Labelling: Footwear must clearly display markings that indicate compliance with EN ISO 20345:2011, including the manufacturer's identification, size, and safety symbols that correspond to the specific protective features (e.g., SB, S1, S3).

- Fit for Purpose: Employers must ensure that all PPE, including safety footwear, is suitable for the tasks at hand. This means choosing footwear that meets the specific safety needs of the job role, such as resistance to heat, cold, chemicals, or punctures.

- Provision by Employer: The regulations state that employers are responsible for providing safety footwear at no cost to employees when the footwear is deemed necessary by a risk assessment.

- Ongoing Maintenance: Employers must also ensure that the footwear remains in good condition, conducting regular checks to identify wear and tear, and replacing any damaged or compromised footwear promptly.

These regulations are enforced by the Health and Safety Executive (HSE), and failure to comply with the standards can lead to penalties or legal consequences, especially in the case of workplace injuries.

The aim is to reduce foot injuries across sectors like construction, engineering, and manufacturing.

Key Safety Footwear Ratings and Standards

Safety footwear ratings and codes provide information about the level of protection they offer. These ratings ensure that the footwear is suitable for various hazardous environments.

Footwear Ratings:

- SB (Safety Basic): This is the base-level rating for safety footwear, requiring only basic toe protection. Footwear with this rating must have a protective toecap that can withstand up to 200 joules of impact. There are no additional requirements for features such as slip resistance or water penetration.

- S1: Footwear with an S1 rating includes all the requirements of SB, plus additional features. S1 footwear provides anti-static properties, heel energy absorption, and fuel oil resistance. This rating is suitable for environments where the primary hazards involve electrical discharges and oil spills.

- S1P: The S1P rating adds further protection to the S1 standard, offering penetration resistance in the midsole (typically with a steel or composite plate). This is essential for environments where sharp objects on the ground, like nails or shards, are a potential hazard.

- S2: Footwear with an S2 rating includes all the protection of S1 but adds water penetration resistance. S2 footwear is ideal for outdoor work environments where exposure to water or damp conditions is common.

- S3: S3 footwear includes all the features of S2 and adds midsole penetration resistance. It’s designed for harsh working environments, offering protection against sharp objects underfoot as well as water penetration.

- S4: Similar to S1 but intended for polymer/rubber boots, S4-rated footwear offers 200-joule toe protection, anti-static properties, and oil resistance, with the additional benefit of being fully waterproof and leakproof due to their molded design.

- S5: S5 footwear builds on the S4 rating by adding midsole penetration resistance. It’s used in high-risk environments that involve water, sharp objects, and slippery surfaces, commonly seen in industries such as construction and agriculture.

Slip Resistance Standards:

- SRA: Slip resistance tested on a ceramic tile floor with a sodium lauryl sulfate solution (similar to soap). It’s commonly required for environments like kitchens or medical facilities where slipping hazards on wet tiles are frequent.

- SRB: Slip resistance tested on a steel floor with glycerol (similar to oil). This is used in environments where oils or lubricants are present, such as workshops or garages.

- SRC: This combines both SRA and SRB testing methods, making SRC-rated footwear highly versatile and the best choice for environments with varied surfaces and slip risks.

ASIDE: There were some amendments to the standards in 2022 not included in this article yet. See the changes here.

The Importance of Slip Resistance in Safety Footwear

Falling, tripping, and slipping are some of the most frequent accidents at work. Slips, trips, and falls accounted for 32% of non-fatal workplace injuries in the UK in 2022/23, making slip-resistant footwear an essential safety measure.

According to the HSE, minimising incidents like these can significantly reduce injury rates and lost workdays.

Industry-Specific Applications of Safety Footwear

Each industry has unique risks and safety requirements, so the type of safety footwear required differs significantly. The following are examples of safety footwear uses in several sectors:

Construction and Engineering

- Primary Hazards: Falling debris, sharp objects, and uneven ground.

- Recommended Footwear: S3-rated boots with midsole penetration resistance and ankle support are essential for protecting against foot injuries. Waterproof and anti-slip features are also recommended for outdoor conditions. Slip-resistant ratings of SRC are often necessary.

Manufacturing and Warehousing

- Primary Hazards: Heavy machinery, slippery floors, and moving objects.

- Recommended Footwear: S1P footwear is generally suitable, providing anti-static properties, penetration resistance, and oil resistance. Slip-resistant footwear is vital in manufacturing plants and warehouses, where spills are common.

Chemical and Oil Industries

- Primary Hazards: Chemical spills, flammable liquids, and oily surfaces.

- Recommended Footwear: S4 or S5 boots offer full waterproof protection and resistance to chemicals, with slip resistance and penetration protection to prevent accidents in hazardous environments.

Agriculture and Food Processing

- Primary Hazards: Wet, muddy conditions, and exposure to chemicals.

- Recommended Footwear: S4 or S5-rated safety wellingtons, which offer full waterproof protection, slip resistance, and fuel/oil resistance. White wellingtons are commonly used in food processing environments for easy visibility of contamination.

How to Select the Right Safety Footwear

Choosing the correct safety footwear for your needs requires assessing workplace hazards and matching appropriate footwear ratings to those risks.

Here's what you should consider:

- Assess the risks: Conduct a risk assessment and identify possible risks such as falling items, slippery flooring, or chemical exposure.

- Check the ratings: Match the identified hazards to the appropriate ratings to ensure your footwear meets EN ISO 20345:2011 requirements.

- Consider Comfort: Safety footwear should be both protective and comfortable to wear for extended periods of time. Lightweight composite-toed boots can help ease foot fatigue.

- Industry Requirements: Some sectors, such as electronics, may require specialised footwear, such as ESD-rated boots, to avoid static discharge.

- Durability and Maintenance: To ensure durability, choose sturdy footwear that can survive difficult working conditions and maintain it on a regular basis.

Proper Care and Maintenance of Safety Footwear

To extend the life of safety footwear and assure continuous protection, proper care and maintenance is necessary. The need for this would be highlighted during a PPE audit specifically for safety footwear.

Here are a few tips:

- Regular Cleaning: Clean your boots on regularly to remove dirt, chemicals, or oils that could damage the material.

- Drying: If your footwear becomes wet, dry it naturally rather than using direct heat sources, which can deform or harm the material.

- Regular inspection: Look for indications of wear and tear, such as cracks, worn soles, or damaged toe caps.

- Storage: Keep boots in a cool, dry area away from chemicals and excessive heat.

By following these maintenance procedures, you can extend the life of your safety footwear and remain compliant with safety standards.

Why Choose XAMAX® for Your Safety Footwear Needs

XAMAX® is more than just a safety supplier – we’re a trusted partner for businesses across the UK. As a BSIF-registered supplier, we guarantee that all our safety footwear complies with EN ISO 20345:2011 standards.

Our extensive range covers every industry, from heavy-duty construction boots to lightweight safety trainers for electronics work. We also offer waterproof wellingtons for industries like food processing and agriculture.

Here’s why businesses trust XAMAX®:

- BSIF Registration: XAMAX® is a British Safety Industry Federation (BSIF) registered supplier, ensuring that all the PPE we provide meets the highest safety standards.

- Expert Advice: Our team is available to guide you through the process of selecting the best safety footwear for your specific needs.

- Competitive Pricing: XAMAX® offers competitive pricing without compromising on quality, ensuring you get the best value for money.

If you're looking to kit out your team with high-quality, compliant safety footwear, look no further than XAMAX®.

Conclusion

Choosing the appropriate safety footwear is crucial to maintaining a safe and productive work environment. The rules, ratings, and standards addressed in this guide lay the foundation for choosing footwear that meets the right safety requirements while protecting workers from different hazards they might face.

From construction and manufacturing to food processing and healthcare, selecting the appropriate footwear is not just about compliance; it’s about reducing injuries, increasing comfort, and enhancing productivity.

By understanding and adhering to key safety standards like EN ISO 20345:2011 and ensuring that your footwear meets the specific needs of your industry, you can help safeguard your workforce against accidents and injuries.

Whether it's for protection against slips, chemical exposure, or heavy impact, providing your staff with the proper safety footwear is a proactive step towards workplace safety.

At XAMAX®, we understand how crucial this is. As a BSiF-registered safety supplier, we offer a range of safety boots and shoes that comply with all necessary standards and regulations.

With our expertise, you can be confident that your team is protected with high-quality, compliant PPE footwear, and our team is ready to help you select the best footwear for your specific needs.

Get In Touch - We're Here To Help

Safety footwear is essential for preventing workplace foot injuries and complying with UK regulations. Understanding the legal obligations, safety ratings, and industry-specific applications helps companies to provide the right level of safety to their employees. This guide covers all you need to know about selecting, using, and maintaining safety footwear. Introduction to Safety Footwear Safety footwear […]

Failure to comply with Personal Protective Equipment (PPE) standards not only endangers worker's lives, but it can also result in significant financial penalties, reputational harm, and even criminal prosecution. While providing proper PPE may appear to be a costly expense, non-compliance can have serious repercussions.

In this article, we'll look at the real-world implications of disregarding PPE regulations in the UK, highlighting cases in which businesses faced legal action, penalties, and other consequences for failing to comply with these essential safety measures.

- Page Contents

- The Legal Costs: Fines and Penalties

- The Human Cost: Injuries and Fatalities

- Reputational Damage

- The Hidden Costs: Absenteeism and Productivity Loss

- Conclusion

The Legal Costs: Fines and Penalties

There may be serious legal consequences if PPE regulations are broken. Employers are required by law to supply and ensure the use of appropriate PPE under the Health and Safety at Work Act of 1974 and the Personal Protective Equipment at Work Regulations of 1992. Failure to do so can result in significant penalties and, in extreme cases, imprisonment.

One notable example from 2024 is the case of a company in Peterborough, which was fined £67,000 after a young worker lost his life due to exposure to chemical fumes. This tragedy could have been prevented by proper PPE and risk assessments. The Health and Safety Executive (HSE) found that the company had failed to ensure adequate safety measures, resulting in a tragic loss and a large financial penalty.

A building materials company, Cemex UK, was fined £1 million after a worker died in a conveyor belt accident in 2017. The investigation revealed that inadequate PPE and safety protocols were major contributing factors.

These examples demonstrate how non-compliance with PPE regulations can lead to life-altering incidents, resulting in both financial and legal consequences.

The Human Cost: Injuries and Fatalities

Apart from the financial penalties, the human cost of not following PPE regulations can be devastating. 400 people were killed at work between 2020 and 2023, many of which may could have prevented with proper PPE.

In one instance, an electrical transmission company failed to provide a proper risk assessment and subsequently inadequate fall protection PPE. This negligence resulted in a 35-year-old worker suffering a catastrophic fall from height, spending 6 months in hospital and being left paralysed and unable to work. A £240,000 fine for the company, but an immeasurable life altering trauma for the worker and his family.

Even less serious incidents, such as eye injuries or exposure to toxic substances, can have consequences that last. The National Health Service (NHS) estimates that thousands of workers suffer eye injuries each year, and 3 out of 5 could be avoided by wearing suitable protective eyewear.

Reputational Damage

As well as the obvious financial expenses and human impact, non-compliance with safety regulations can have long-term repercussions. Companies that violate safety standards often find it difficult to re-establish confidence with employees, customers, and partners. This could result in a drop in business and problems maintaining qualified staff members.

A big UK construction firm, received unwanted media scrutiny and a £275,000 fine when many safety breaches came to light after a fatal incident, including insufficient PPE on-site. One worker was killed and another seriously injured when the scissor lift they were using was pushed over by a nearby crane.

HSE found the incident could have been prevented had Balfour Beatty implemented better controls and put in place better communication between contractors.

Although the firm will probably recover, the harm to its brand and reputation could take years to repair.

The Hidden Costs: Absenteeism and Productivity Loss

The actual cost of workplace accidents exceeds fines and legal expenses. Injuries or health difficulties caused by a lack of personal protective equipment could result in long-term absenteeism and decreased productivity. Even a minor absence due to injury can cause significant delays to projects in sectors like construction and manufacturing.

For example, the HSE discovered that occupational injuries, typically caused by inadequate PPE, led to approximately 35.2 million working days missed in 2022/23. The economic impact of these lost working days, along with higher insurance rates, may be devastating for businesses.

Conclusion: Investing in PPE Saves Lives and Money

The cost of non-compliance with PPE and Health 7 Safety requirements are clear: penalties, legal action, and the risk of death or serious injury.

On the other hand, ensuring your company complies with regulations correctly protects not just the workforce but also your organisation's reputation and legal standing. Investing in high-quality PPE and performing frequent audits are critical steps towards protecting both your staff and your bottom line.

Failure to comply with Personal Protective Equipment (PPE) standards not only endangers worker’s lives, but it can also result in significant financial penalties, reputational harm, and even criminal prosecution. While providing proper PPE may appear to be a costly expense, non-compliance can have serious repercussions. In this article, we’ll look at the real-world implications of disregarding PPE […]

The British weather is (in)famous for its rain, meaning that those who work outside are at risk of getting wet. Are there any specific ‘working in the rain’ regulations? What are an employers’ responsibilities when employees are working in wet weather? Do you continue to work in the rain?

- What Should You Know?

- PPE Regulations

- Weather Exposure

- Protecting Yourself from the Elements

- Legal Requirements for Workplace Temperature

- Prioritise Safety in Adverse Conditions

What Should You Know About Working in the Rain?

There are no UK regulations to say that workers cannot work in the rain. However, safety measures still need to be in place. Employers need to provide suitable protective clothing for employees that may need to be insulating or heat resistant and slip-resistant safety footwear.

It is important to acclimatise your workers to their environment. Train your workers on any precautions they need to take and supervise the environment to make sure everyone is as safe as possible.

PPE Regulations

The Personal Protective Equipment at Work Regulations of 1992 specifies that employers provide their staff with free protective equipment. The equipment should be fit to use, fit correctly, and be maintained. Employers must also provide training on how to use the equipment.

Updated in 2002, regulations note that equipment must be CE-marked. It is also important to make sure your health and safety policy is up to date.

Weather Exposure

Snow exposure can increase the likelihood of accidents such as slipping and falling. But most do not realise rain and cold can be just as damaging.

Those working in the rain are just as likely to have an injury and the single most common injuries caused in the UK are slipping and tripping.

When driving, stopping distances can double, so it is important that your workers driving vehicles know of conditional changes and adapt.

Exposure to cold and rain can cause cold stress, chilblains and, in more serious cases, hypothermia and frostbite.

Chilblains are itchy red patches on the skin caused by being in the cold. They appear on fingers and toes and can appear on your face and legs when exposed to cold and damp conditions.

Frostbite causes the affected parts to feel cold and painful. It can affect any part of your body.

Hypothermia results when the body temperature drops too low. If this happens, you will be fatigued, shiver, lose coordination, and can become confused. Your skin may turn blue, have dilated pupils, a slow pulse, may become unconscious, slowed breathing, and stop shivering.

Protecting Yourself from the Elements

In rainy conditions, your workers will want waterproof trousers, waterproof coats and waterproof shoes or safety boots. Waterproof clothing, however, is not always windproof, and after hours of exposure, it is not always waterproof either. When you are wet and cold, you are at a greater risk of making mistakes and poor decisions that could result in a safety issue.

If hi vis is required, opt for a waterproof hi vis over-trouser and jacket set and make sure the clothing meets PPE regulations.

Legal Requirements for Workplace Temperature

The law informs us of the minimum workplace temperature but not the maximum. Temperatures indoors have to be “reasonable.”

The minimum temperature is 16° Celsius. If you are working and moving rigorously, such as outdoor work, the minimum temperature should be at least 13° Celsius. However, the grey area is that employers have the duty to determine what is considered reasonable and comfortable.

A thorough risk assessment should be done in all conditions including rainy conditions and your employer has a duty to protect you from harm.

Prioritise Safety in Adverse Conditions

Make sure you have site supervisors who are trained in recognising conditions caused by the rain and cold, such as frostbite, chilblains, and hypothermia. Report all incidents and treat immediately.

It is also a good idea to limit exposure and rotate workers so that everyting works properly. For example, since waterproofing does not always last all day, give your workers opportunities for breaks, to change clothes, and get dry and warm before sending them back out in those conditions again.

Rotate your workers to avoid these problems too, or on wet and cold days try to find alternative jobs. Always make sure your staff have the right equipment for conditions.

Conclusion

There are no regulations about working in the rain but there still needs to be safety measures in place. Employees must equip their staff with free equipment and provide training on how to use it.

Your staff are just as likely to have an injury in the rain as they are in the snow. It is important to protect your workers with the right workwear, such as waterproof clothing and safety boots.

Make sure you are adhering to the Health & Safety laws and check the temperature your staff are working in. Most importantly, prioritise the safety of your workers.

The British weather is (in)famous for its rain, meaning that those who work outside are at risk of getting wet. Are there any specific ‘working in the rain’ regulations? What are an employers’ responsibilities when employees are working in wet weather? Do you continue to work in the rain? What Should You Know About Working in the Rain? […]

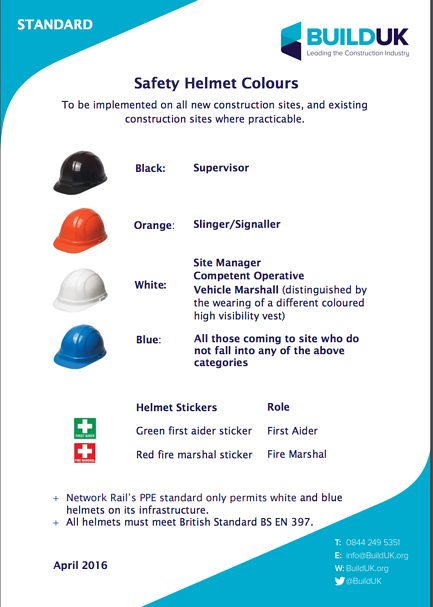

As of January 2017, Build UK, who represents some of the UK's biggest contractors and trade associations, has mandated hard hat colour codes.

Excepting Network Rail workers, whose sites only permit white and blue safety helmets, all other construction sites - new and existing - will be expected to change their helmet colours according to the wearer's site role.

Need Hard Hats with logos? XAMAX® is your perfect safety headwear print supplier.

Why were the colour codes changed for hard hats on sites?

The colour coding system was released April 2016, and is designed to identify workers by their safety qualifications. Each different colour hard hat has a different meaning, and it's important we take note.

The system is intended to reduce on-site dangers by making it easier to note the experience and expertise of each person on a construction site. Those trained in first aid, and fire marshals will wear stickers on their helmets for easy identification.

Do you need a Hard Hat or a Bump Cap? Bump caps are not covered by these changes.

What do the new hard hat colours mean?

The new hard hat colour codes are:

- Black: Supervisors

- Orange: Slinger/Signaller

- White: Site Manager / Competent Operative / Vehicle Marshall (also wears a different coloured Hi Vis vest)

- Blue: Inexperienced Person / Visitor / Apprentice / Architect / Anyone else who doesn’t fall into the above categories.

- Green First Aid + Sticker: First Aider

- Red Fire Marshal + Sticker: Fire Marshal

Images show the Portwest Safety Helmet, available in all mandated colour codes.

To reiterate, these standards and the new colour coding will be industry recognised, so - wherever you are in Britain - you’ll know who does what and who is qualified in various safety measures.

That means no more green and yellow hard hats on the highway.

Black Hard Hat Meaning

If you see a black hard hat wandering around the construction site, you can be sure that's some sort of supervisor or foreman.

Any problems you need help with, the black tops are the people you go to.

They'll also be the ones calling you out if you're slacking!

Orange Hard Hat Meaning

If you're on site and you need a ton of bricks shifting, or a joist lifting into place, you need to look for an orange hard hat. These personnel will be the ones trained, qualified and authorised to sling the weights to be lifted. Slinging isn't an easy job and requires skill and training to ensure weights are evenly distributed to ensure a safe lift.

The crane operators will need hand signals to know when it's safe to lift too. These have to be precise and conspicuous, so this is another trained skill the orange tops have. Orange hats will likely have other skills. They could be a brickie, a joiner, and electrician or pretty much any construction trade. The orange simply signifies that the wearer is also trained to sling and signal.

White Hard Hat Meaning

These hard hats have multiple uses. The site manager will be wearing a white hard hat on the construction site to signify that he's in charge.

But then, anyone who is skilled in their trade and classed as a "competent operative" would be wearing a white hard hat too. That clash between those who do the work and those who create the work may cause confusion, but it's likely the site manager will be wearing a suit and not grafter's workwear.

A vehicle marshal will be wearing white too, but there's a very good chance they'll be wearing Class 3 hi-vis (at least should be) which would be marked on the back as a marshal.

Blue Hard Hat Meaning

This colour of helmet is reserved for those who shouldn't really be left unsupervised on a building site. Apprentices will be wearing a blue hard hat, as will any visitor to the site.

Health & Safety is everyone's responsibility. If you see a blue hat working alone or wandering around unsupervised, you should look for a black hat and let them know.

Red Hard Hat Meaning

Oh My Lord there's a FIRE!

When the alarm goes and everyone exits in a safe and orderly manner, it will be a red hard hat directing you. You do as they say if you want to stay alive. This is an important position that requires extensive training and responsibility. There will likely be a sticker on their hat that signifies they are a fire marshal, but not every time.

Green Hard Hat Meaning

There's not a tradesman in history who hasn't skinned a knuckle, cut their finger or taken a knock to the head. When those incidents happen (and they do happen) and somebody is hurt, it is a first aider you look for. By looking for a green hard hat you will find the first aider more easily and quickly.

As with the red tops, green tops will likely have a first aid sticker on their helmet that comes with the job.

What happens if I don't follow the colour safety rules?

The new regulations WILL cost companies if they don’t comply immediately and HSE may halt projects if site workers aren’t wearing the correct coloured hard hats.

This happened in 2008 in Aberdeen when a £285 million construction project was stopped for incorrect hat colours, breaking Health and Safety regulations.

There is no excuse really. Hard hats are a relatively inexpensive piece of PPE, especially considering the dangers of not using them properly.

How much will all this cost me?

It is better to ensure that you and your colleagues are safe on site, than it is to hope for the best and save a few quid. Fines are being handed out and workers are getting injured.

In the long run, these regulations mean lower costs to employers, which is good news for companies. With fewer hard hat colours, companies will have to buy fewer variants, but initial replacement may be costly, if you haven't done it already.

Although by now, you probably should have got al this sorted. Hard hats only have a certain shelf life anyway, as the plastic weakens and deteriorates over time, depending on the weather conditions of your particular site.

There should either be an embossed or printed ‘best before’ date on your helmet, or some brands have stickers that fade over time, letting you know when it’s time to replace it.