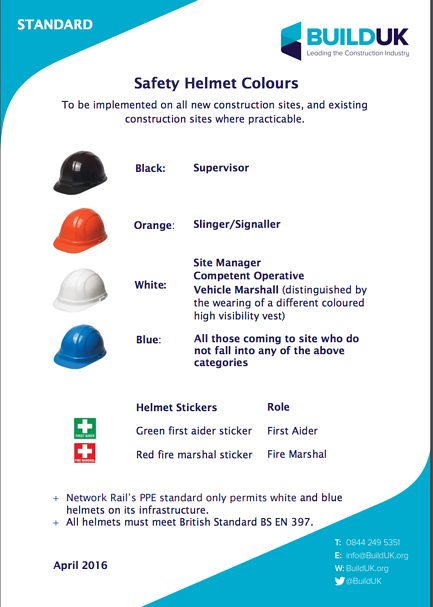

As of January 2017, Build UK, who represents some of the UK's biggest contractors and trade associations, has mandated hard hat colour codes.

Excepting Network Rail workers, whose sites only permit white and blue safety helmets, all other construction sites - new and existing - will be expected to change their helmet colours according to the wearer's site role.

Need Hard Hats with logos? XAMAX® is your perfect safety headwear print supplier.

Why were the colour codes changed for hard hats on sites?

The colour coding system was released April 2016, and is designed to identify workers by their safety qualifications. Each different colour hard hat has a different meaning, and it's important we take note.

The system is intended to reduce on-site dangers by making it easier to note the experience and expertise of each person on a construction site. Those trained in first aid, and fire marshals will wear stickers on their helmets for easy identification.

Do you need a Hard Hat or a Bump Cap? Bump caps are not covered by these changes.

What do the new hard hat colours mean?

The new hard hat colour codes are:

- Black: Supervisors

- Orange: Slinger/Signaller

- White: Site Manager / Competent Operative / Vehicle Marshall (also wears a different coloured Hi Vis vest)

- Blue: Inexperienced Person / Visitor / Apprentice / Architect / Anyone else who doesn’t fall into the above categories.

- Green First Aid + Sticker: First Aider

- Red Fire Marshal + Sticker: Fire Marshal

Images show the Portwest Safety Helmet, available in all mandated colour codes.

To reiterate, these standards and the new colour coding will be industry recognised, so - wherever you are in Britain - you’ll know who does what and who is qualified in various safety measures.

That means no more green and yellow hard hats on the highway.

Black Hard Hat Meaning

If you see a black hard hat wandering around the construction site, you can be sure that's some sort of supervisor or foreman.

Any problems you need help with, the black tops are the people you go to.

They'll also be the ones calling you out if you're slacking!

Orange Hard Hat Meaning

If you're on site and you need a ton of bricks shifting, or a joist lifting into place, you need to look for an orange hard hat. These personnel will be the ones trained, qualified and authorised to sling the weights to be lifted. Slinging isn't an easy job and requires skill and training to ensure weights are evenly distributed to ensure a safe lift.

The crane operators will need hand signals to know when it's safe to lift too. These have to be precise and conspicuous, so this is another trained skill the orange tops have. Orange hats will likely have other skills. They could be a brickie, a joiner, and electrician or pretty much any construction trade. The orange simply signifies that the wearer is also trained to sling and signal.

White Hard Hat Meaning

These hard hats have multiple uses. The site manager will be wearing a white hard hat on the construction site to signify that he's in charge.

But then, anyone who is skilled in their trade and classed as a "competent operative" would be wearing a white hard hat too. That clash between those who do the work and those who create the work may cause confusion, but it's likely the site manager will be wearing a suit and not grafter's workwear.

A vehicle marshal will be wearing white too, but there's a very good chance they'll be wearing Class 3 hi-vis (at least should be) which would be marked on the back as a marshal.

Blue Hard Hat Meaning

This colour of helmet is reserved for those who shouldn't really be left unsupervised on a building site. Apprentices will be wearing a blue hard hat, as will any visitor to the site.

Health & Safety is everyone's responsibility. If you see a blue hat working alone or wandering around unsupervised, you should look for a black hat and let them know.

Red Hard Hat Meaning

Oh My Lord there's a FIRE!

When the alarm goes and everyone exits in a safe and orderly manner, it will be a red hard hat directing you. You do as they say if you want to stay alive. This is an important position that requires extensive training and responsibility. There will likely be a sticker on their hat that signifies they are a fire marshal, but not every time.

Green Hard Hat Meaning

There's not a tradesman in history who hasn't skinned a knuckle, cut their finger or taken a knock to the head. When those incidents happen (and they do happen) and somebody is hurt, it is a first aider you look for. By looking for a green hard hat you will find the first aider more easily and quickly.

As with the red tops, green tops will likely have a first aid sticker on their helmet that comes with the job.

What happens if I don't follow the colour safety rules?

The new regulations WILL cost companies if they don’t comply immediately and HSE may halt projects if site workers aren’t wearing the correct coloured hard hats.

This happened in 2008 in Aberdeen when a £285 million construction project was stopped for incorrect hat colours, breaking Health and Safety regulations.

There is no excuse really. Hard hats are a relatively inexpensive piece of PPE, especially considering the dangers of not using them properly.

How much will all this cost me?

It is better to ensure that you and your colleagues are safe on site, than it is to hope for the best and save a few quid. Fines are being handed out and workers are getting injured.

In the long run, these regulations mean lower costs to employers, which is good news for companies. With fewer hard hat colours, companies will have to buy fewer variants, but initial replacement may be costly, if you haven't done it already.

Although by now, you probably should have got al this sorted. Hard hats only have a certain shelf life anyway, as the plastic weakens and deteriorates over time, depending on the weather conditions of your particular site.

There should either be an embossed or printed ‘best before’ date on your helmet, or some brands have stickers that fade over time, letting you know when it’s time to replace it.

There is no excuse for providing or wearing an unsafe hard hat, so make sure everyone is covered correctly at all times.

Can I still add my logo to a hard hat?

All helmets must meet British Standard BS EN 397, so full wrap stickering won't be allowed. You can still safely have your logo printed onto a hard hat so long as your supplier adheres to safety standards.

Just one more reason to always choose a BSiF Registered Safety supplier like XAMAX® as your trusted customisation specialist.

Where can I get hard hats with my logo printed on?

XAMAX® can supply you with high quality, fully compliant and customised hard hats at highly competitive prices. If your company needs new hard hats, check out our selection here;

All safety helmets and hard hats are available in the four regulation colours, meet all PPE standards and are available to add your logo to.

XAMAX® use direct pad printing techniques as well as indirect printing on our hard hats to ensure you get the quality you deserve.

What was the old hard hat colour coding system?

For those who are curious, the old regulations necessitated a staggering seven colours of hard hat: white, green, yellow, brown, blue, orange, and grey.

- White was for managers, foreman, engineers, or supervisors

- Green was for safety inspectors, new workers, or probationary staff;

- Yellow was for general labour and earth moving operators; brown was for welders and other high-heat workers

- Blue was for carpenters and technical operators, including electricians

- Orange was worn by road crews

- Grey was worn by site visitors, or those who forgot or misplaced their hard hat. Sometimes a bright pink hard hat was worn as a semi-punishment.

Forget those seven colours. Now, there are only a simplified four colours to remember, which should make it easier and safer for everyone.

What will companies do with all of the old hard hats? And - most pressingly - can Bob the Builder be fined for wearing his yellow hat on a construction site instead of a white one?

Yes he can.

Of course, it's important to remember that these colour codes for hard hats only refer to construction sites in the UK. Any other working environment can pretty much use any colour they like.

As of January 2017, Build UK, who represents some of the UK’s biggest contractors and trade associations, has mandated hard hat colour codes. Excepting Network Rail workers, whose sites only permit white and blue safety helmets, all other construction sites – new and existing – will be expected to change their helmet colours according to […]

Head injuries are often serious and all too often life threatening. It is important, when working in hazardous industries, you and your employees are protected with some form of head protection such as a Hard Hat or a Bump Cap.

Hard Hats are very different pieces of PPE from Bump Caps and they both perform different safety functions, so it is important you understand the differences between them.

Each year around 65,000 need time off of work due to head injuries. Over 1,000 workers die from injuries sustained on the job. Do you know the difference between bump caps and hard hats?

- Page Contents

- The Difference Between Bump Caps and Hard Hats

- What Is A Bump Cap?

- What Is A Hard Hat?

- Are Bump Caps Allowed in Construction?

- Conclusion

What is the Difference Between a Bump Cap and a Hard Hat?

Bump caps are safety equipment that protect the wearer from minor head bumps and lacerations, but not from falling or flying objects. You should use safety bump caps when there is a risk of impact between the head and stationary objects such as low ceilings, the underside of a vehicle (for mechanics, especially) and overhead piping.

It is the bump cap's removable safety insert that protects the head and not the fabric cap itself. This allows for easy cleaning and customisation techniques such as embroidery.

When there is a risk of impact with moving objects, we must use a hard hat.

Both bump caps and hard hats have safety requirements which are defined in the safety standard BS EN 812:2012. They test bump caps for a lower level of severity, measuring essential performance and safety requirements. Also, bump caps provide protection against sharp objects and some against cold temperatures.

Hard Hats (aka: Safety Helmets) are an essential piece of PPE equipment (PDF). It is made of rigid material such as a polymer, metal or fibreglass to protect the wearer when working in places where debris and falling objects cause a potential risk of head injury.

Mandatory on building sites, hard hats will withstand major impact to protect the wearer’s head from impact. Hard hats also protect the wearer from different weather conditions.

Both hard hats and bump caps provide some level of head protection. What you need for your industry depends on the potential hazards you and your workers are exposed to.

What is a Bump Cap?

Also know as a bump hat, these are inexpensive and easy to wear, almost like a safety version of a baseball cap, but are not for really high impact risks.

Effectiveness of Protection

A bump cap protects you from stationary objects and nothing that is high impact. They are, as the name suggests, simply to protect against bumping your head.

Cost

Bump caps sit at around the £6-£10 range per unit but are cheaper when ordering in bulk. However, some companies offer winter hard caps around the £15-£25 price point.

Maintenance

Inspect, maintain, replace. Replace anything that is damaged. Clean with mild soap and water. Do not use chemicals on the cap or shell.

Lifespan

You can perform a shell test by pressing down with both hands. If the material springs back, your bump cap is still effective. Compare with the elasticity of a new shell. If it does not have the same properties or has cracks, it needs to be replaced in order to comply with EN812:2012.

Ease of Wear

Look for adjustable straps for an easy secure fit. Caps do not add height to your head and reduce your chances of injury from bumping into objects. You can get hot and sweaty with prolonged use if the model does not provide ventilation.

Bump caps are more lightweight compared to hard hats and do not impair vision.

What is a Hard Hat?

Also known as a Safety Helmet, hard hats are exactly what they say they are - a hat, that is hard - designed to protect you from impacts that would otherwise result in serious head injury or even death.

Effectiveness of Protection

Hard hats protect you from high-impact debris by absorbing the shock of the impact and offer the best head protection when worn correctly. Hard hats are resistant to penetration, falling objects and extreme heat.

Cost

The cost of hard hats can range anywhere from £3 per unit to £20-£30 per unit. The average price range is £9. When bought in bulk, it reduces the cost significantly.

Maintenance

Just like bump caps, follow the "inspect, maintain and replace" rules. Make sure you replace any damaged parts and clean with mild soap and water. Do not use chemicals on your hard hat - that includes permanent markers!

Lifespan

You need to replace the suspension at least every 12 months and the shell every 2-5 years. The lifespan of you hard hat relies on your work environment such as:

- Sunlight exposure

- Temperature extremes

- Chemical exposure

- Frequency of use

You need to inspect your hard hat daily to determine if the shell, suspension or the entire unit needs replacing. Also, if your hard hat has sustained an impact, you need to replace it. Replace your hard hat if it has:

- Cracks

- Dents

- Cuts/gauges

- Frayed straps

- Tears

- Flexibility

Heat, sunlight and chemical exposure also effects your hard hat. They can make the shell become chalky, dull and less flexible.

Ease of Wear

Hard hats need to be fitted to make sure they are comfortable. They are adjustable. You and your staff can wear items such as bandanas, skull-caps and hoods underneath your hard hat as long as they are smooth on top of your head. Make sure you avoid pressure points. Your hard hat needs to fit snuggly.

Hard hats often need replacing to offer the highest level of protection so it is better value when you buy them in bulk. Any workplace with the hazard of high-impact debris requires hard hats to be worn.

You should also be aware that there are different colours of hard hats for different job roles. you can learn more about hard hat colour coding here.

Are Bump Caps Allowed on Construction Sites?

Probably not.

There is no hard and fast rule here, except the suitability of the headwear for the environment you are in. If it's possible that someone could drop a brick on your head, then a bump cap is not going to protect you in the way a hard hat would.

Your managers will know this and will probably set a site/company wide rule.

So if the PPE sign says you must wear a Hard Hat, then a bump cap is not suitable.

Conclusion

The type of head protection you need depends on your workplace and working environment. If there is a risk of high-impact, you need to wear hard hats. You should only use bump caps to protect you from minor head bumps and cuts.

It is important you do not skimp on head protection. Injury of a worker will cost businesses more in the long run than the head protection itself.

Head injuries are often serious and all too often life threatening. It is important, when working in hazardous industries, you and your employees are protected with some form of head protection such as a Hard Hat or a Bump Cap. Hard Hats are very different pieces of PPE from Bump Caps and they both perform […]