How To Use Screen Printing Techniques On Custom Workwear

This post looks to show you how to use screen printing techniques on custom workwear so that you know the strengths and weaknesses of the process. From how screen printing works, to when to use it so it's most cost effective. And more.

The questions we'll be answering in this post are:

What Looks Can Screen Printing Achieve? Who Should Use It? What Is Screen Printing? Is It Expensive? What To Look Out For When Screen Printing Workwear What Other Options Are There To Screen Printing?

So, you can get the most informed picture possible of whether screen printing is right for your custom workwear. Let's get started.

What Looks Can Screen Printing Techniques Achieve? Who Should Use It?

Screen printing achieves bold, vivid and colourful finishes. It's perfect for those companies with modern, dynamic logos and those who need to create a striking look.

It's perfect for informal businesses like bars, restaurants, retail stores or anybody in active and physical industries - everything from construction and manufacturing to university SU or promo teams.

Any company who is looking to get high numbers of similar items should definitely consider screen printing.

What Is Screen Printing? Is It Expensive?

Screen printing is a form of what is called "direct printing".

"Direct printing" means that the printing process goes directly onto the object itself - in this case; your workwear, uniform or business clothing items. "Indirect printing" refers to other techniques, like vinyl transfers, which are printed digitally on an additional material/surface, which is then added onto the garment.

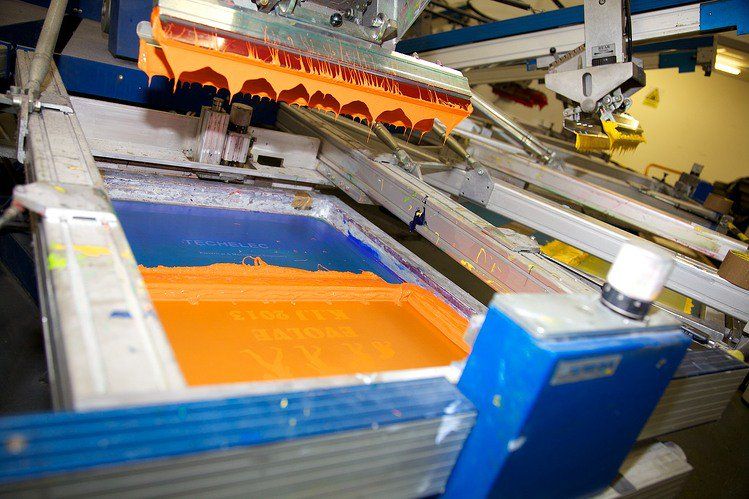

Screen printing uses screen presses and mixed inks to put one colour at a time onto/into the garment (see the picture above). A press needs to be created and set up for each colour in the process. This stage involves using wax creations of images in order to make a precise screen for printing.

The printer we use here at XAMAX® is a 12 station, MHM S-Type machine. The best in the world. The printed garments go through a dryer which cures the ink at 180 degrees, in order to give the most consistent finish possible.

Screen printing has a reputation of being expensive - but this is only the case if you use it for high numbers of colours and low numbers of garments (less than 100). It's actually a very cost effective means of printing high numbers (more than 100) of the same garment when using a low number of colours in the printing.

What To Look Out For When Screen Printing Workwear Numbers

As said, a screen is required for each colour involved. To illustrate a problem to watch out for, if your logo features 4 colours and you only want 5 t-shirts printing for promo events; this would work out incredibly expensive.

But if you want 500 t-shirts for a bigger team project/a new uniform, it would work out very cost efficient.

This is because (roughly speaking) the same amount of labour and skill is involved in setting up the 4 screens, but they're being used on 500 times instead of 5.

Textures

Another thing to look out for is the mixing of textures and materials. Consider the different feel to the cotton used in a polo shirt compared to a crew neck t-shirt. The smoother feel of the latter gives a much better surface for screen printing than the more porous and absorbent pique of the former.

The final appearance of your screen printed logo would look different due to the way the ink reacts with the different materials. This means that you might think you're ordering workwear which uses the 4 screens 500 times, but if the order is half black polo shirts and half white t-shirts, you'd need 8 screens and 8 mixes of ink.

This drives up the cost.

Also, you can't screen print onto fleece. Before you know, if you're ordering a t-shirt, polo shirt and fleece as part of your custom workwear uniform, you need three different print processes.

Speak to your supplier for more advice about achieving a consistent look and which techniques are best for each garment; screen print, indirect printing or embroidery.

What Other Options Are There To Screen Printing?

If these suggestions don't exactly fit your needs, you should look into some other options available for making your custom workwear.

Indirect printing techniques can work out more cost effective for highly elaborate designs and colour schemes or for those looking for a short term use or low number order.

Whereas embroidery is another option. It's a classic branding technique which is very, very long lasting, intricate and professional in appearance.

Find Out A Bit More About Screen Printing

And other types of printing and embroidery too. Open this quick, free and helpful guide to choosing between Print v Embroidery:

- Band Merchandise 101: Designing T-Shirts for Merchandise - 28th November 2024

- Wholesale T-Shirts for Retail Resale: A Guide for Shops and Boutiques - 28th November 2024

- Branding T-Shirts as Workwear: Practical and Cool Solutions for Summer - 28th November 2024